JS Series Double Shaft Concrete Mixer

- JS500 double shaft

concrete mixer - JS750 double shaft

concrete mixer - JS1000 double shaft

concrete mixer - JS1500 double shaft

concrete mixer - JS2000 double shaft

concrete mixer

JS series concrete mixer is designed with double shaft. It is a kind of forced mixer which stirs and mixes materials by high speed rotation of mixer shaft in mixing drum. This mixing way makes it essentially differs from gravity type mixer.

Advantages

1. The JS series double shaft concrete mixer adopts two solid shaft to ensure more uniform mixing. The service life of this shaft is twice longer than that of the plain one.

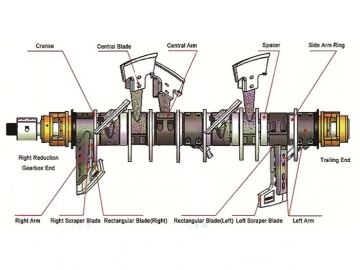

2. This concrete mixing machine is specially designed with 14 mixing blades which can ensure the equipment short blending cycle and efficient capacity.

3. Our double shaft concrete mixing machine features easier operation and maintenance due to its reasonable structure and dedicated design. Alternative design as required by users is also available.

4. It is applicable to continuous mixing and full automatic computer control, so it boasts high efficiency and productivity. For instance, the smallest model of this concrete mixers can achieve 25 cubic meters output.

5. The built-in blades, liner, and mixing arm of the JS series double shaft concrete mixer have following advantages:

(1) Being made of manganese steel, they feature superior wear-resisting performance and strong impact resistance.

(2) The life span is 3-5 times longer than that of ordinary alloy, so replacement cycle of the internally installed equipment is greatly prolonged, and the maintenance cost is significantly reduced.

Applications

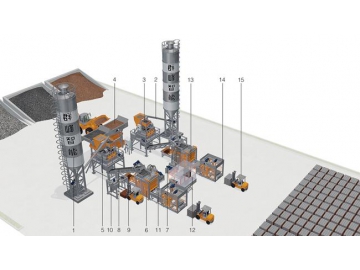

1. JS series double shaft concrete mixer can work alone. Sand and aggregate can be fed manually. Also, it can be combined with PLD batcher to form a simple mobile mixing plant.

2. If the sand and aggregate can be fed by a series of equipment such as matched batching machine, screw conveyer, cement bin, full automatic weighing system and control system, the complete equipment can be called full automatic mixer or mixing building as well as mixing plant.

3. This industrial concrete mixer can be used to produce harsh, plastic, or pasty concrete, lightweight aggregate, and all kinds of mortar.

4. Our twin-shaft concrete mixer has found a wide range of application in all types of large, medium and small factories for prefabrication, as well as construction projects such as road, bridge, water conservancy, wharf, etc.

| Item | ||||||

| Discharging volume (L) | 500 | 750 | 1000 | 1500 | 2000 | |

| Feeding volume (L) | 800 | 1200 | 1600 | 2400 | 3200 | |

| Capacity (m³ /h) | ≥25 | ≥35 | ≥60 | ≥90 | ≥120 | |

| Max. aggregate diameter(mm) | ≤40/60 | ≤40/60 | ≤60/80 | ≤60/80 | ≤60/80 | |

| Production cycle (s) | 72 | 72 | 60 | 60 | 60 | |

| Weight (Kg) | 4000 | 5500 | 8700 | 11130 | 11130 | |

| Dimensions L*W*H(mm) | Transportation | 3050*2300 *2680 | 3650*2600 *2890 | 4640*2250 *2250 | 5058*2250 *2440 | 5860*2250 *2735 |

| Working | 4461*3050 *5225 | 4950*3650 *6225 | 8765*3436 *9540 | 9645*3436 *9700 | 10720*3870*10726 | |

| Mixing blades | Speed (r/min) | 35 | 31 | 25.5 | 25.5 | 23 |

| Quantity | 2*7 | 2*7 | 2*8 | 2*10 | 2*10 | |

| Mixing motor | Model | Y180M-4 | Y200L-4 | Y225S-4 | Y225M-4 | Y280S-4 |

| Power (KW) | 18.5 | 30 | 37 | 45 | 75 | |

| Hoisting Motor | Model | YEZ132S-4-B5 | YEZ132M-4-B5 | YEZ160S-4 | YEZ180L-4 | YEJ180L-4 |

| Power (KW) | 5.5 | 7.5 | 11 | 18.5 | 22 | |

| Water pump motor | Model | 50DWB20-8A | 65DWB35-5 | KQW65-1001 | KQW65-1001 | CK65/20L |

| Power (KW) | 0.75 | 1.1 | 3 | 3 | 4 | |