SAWL Steel Pipe

Advantages

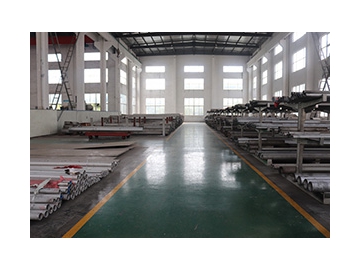

1. SHENGLI adopts self-developed JCOE manufacturing technique to produce the SAWL steel pipe. Our production line realizes automatic computer control to ensure stable pipe quality and production efficiency.

2. The production technology of longitudinal submerged arc welding steel pipe is relatively flexible, although production efficiency is a bit lower than that of high-frequency longitudinal welded pipe and helical welded pipe.

3. This LSAW steel pipe is made adopting hot rolled steel strip of different thickness, and the strip is directly formed via longitudinal welding at normal temperature. Meanwhile, high-frequency solid-state induction welding craft is utilized.

4. By adopting this method, elastic recovery stress of the JCOE welded tube is small.

5. Solid-state welding craft and on-line heat treatment guarantee weld bead strength and mechanical properties, thus improving bearing capacity and compression strength of the steel pipe.

Application

This SAWL steel pipe is mainly used as oil and gas pipeline. It is also used to transport coal gas, water, fuel gas, air, heating steam and common fluids.

Parameters

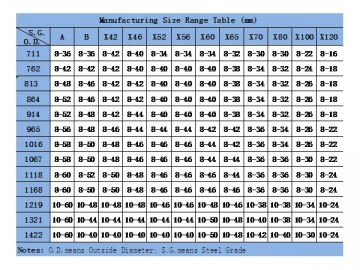

1. Diameter: Φ711-Φ1422mm

2. Length: 8-12.5m

3. Maximum wall thickness: 40mm (X80), 60mm (yield strength≤345MPa)

4. Maximum steel grade: X80

5. Standard: API Spec. Q1, GB/T9711, technical specifications required by customer

Work Flow

The SAWL steel pipe is manufactured in following procedures

→ → → → → → → → → → → → → → → → → →