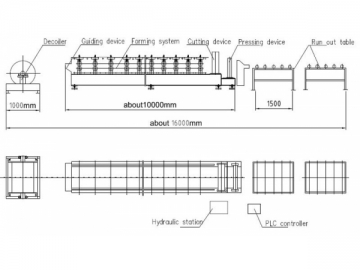

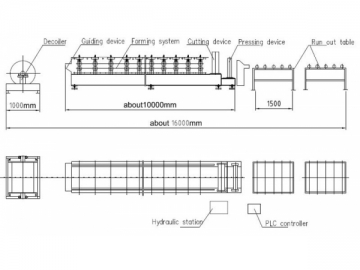

Roll Forming Machine (For Metal Roof Tiles)

The roll forming machine is a perfect solution for sheet metal fabrication, and it is widely used for producing metal roof tiles.

Technical Data of the Roll Forming Machine| Suitable material | Q235 color steel sheet; 0.4-0.6mm |

| Working speed | about 3.0m/min |

| Step distance | Adjustable according to requirement (>=250mm) |

| Power Requirement | Main motor power: 5.5 Kw (Depend on final design) |

| Hydraulic station power | 5.5Kw (Depend on final design) |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

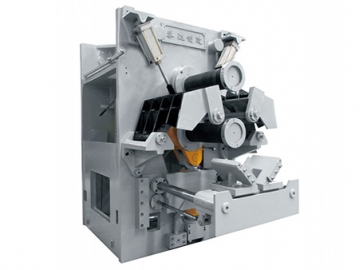

| Material of cutter, pressing die | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, Dia. is 72mm. Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 10500KGS |

| Machine's size | about 18m×1.8m× 1.5m (Depend on final design) |

Advantages of the Roll Forming Machine

1. Anti-rust roller: The forming rollers for the sheet metal coil processing equipment are CNC processed to improve precision, and come with 0.05mm thick chrome plating to enhance durability.

2. Heat treatment: To avoid deformation of the cutting frame, special heat treatment is performed to eliminate the steel stress.

3. Cutter blade: Made of Cr12 mould steel, the cutter blade for the roll forming machine also undergoes quenching treatment, which ensures extended lifespan.

4. High precision: The metalworking machinery delivers very high precision, because of its CNC machined forming rollers and the roller shafts which are processed by grinding machine for at least twice.

5. User-friendly operation: The sheet metal forming machine is configured with Mitsubishi PLC control system with touch screen, which ensures easy operation and user-friendly man-machine interaction.

6. Excellent services: Upon request, we can send technicians to our clients' factories, so as to assist in machinery installation and operator training. All our roll forming machines are available with lifetime service.

-

Roller is made of high grade No.45 forged steel plated with hard chrome, by digital-controlled procession.

-

Metrocopo tile

Your tile forming machine can be designed here.