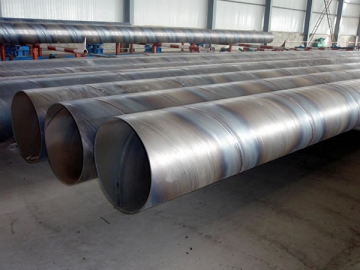

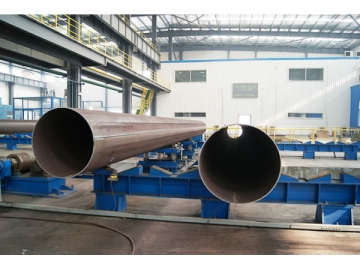

LSAW Steel Pipe

By carrying out standard Non-Destructive Detections on our LSAW pipes, we ensure that our pipes serve our customers well. Our LSAW steel pipes are ideal pipes for large-scale pipeline engineering, petroleum, water or natural gas transportation and urban pipe network construction, and piling.

Process:

LSAW (Longitudinal Submerge-arc Welded), UO(UOE), RB(RBE), JCO(JCOE)

DSAW (Double Submerged arc welded)

Quality Standard:

LSAW, DSAW:

API 5L Line Pipe for oil and gas

ASTM A53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded

ASTMA252 for piling pipe

EN10217 Welded steel tubes for pressure purposes, Technical delivery conditions, Non-alloy steel tubes with specified room temperature properties

GB/T3091 Welded steel pipe for low pressure liquid delivery

GB/T9711 Petroleum and natural gas industries--Steel pipe for pipelines

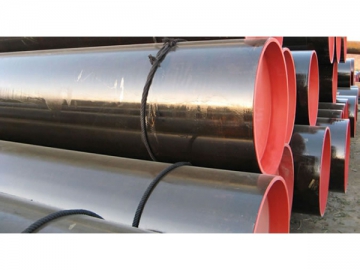

Coating Standard:

ANSI/AWWA C104/A21.4 American National Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water

ISO 21809 Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems

DIN 30670 Polyethylene coatings of steel pipes and fittings

Steel Grade:

EN10217: S185, S235, S235JR, S235 G2H, S275, S275JR, S355JRH, S355J2H,

ASTM A 53: Gr. A, Gr B, Gr C, Gr. D

API 5L: A, B, X42, X46, X52, X56, X60, X65 X70

ASTM A252 GR.B GR.C

ST37, ST44, ST52

GB/T9711: L175, L210, L245, L290, L320, L360, L290, L320, L360, L390, L415, L450, L485, L555

GB/T3091, SY/T5037, SY/T 5040,CJ/T 3022:Q195, Q215, Q235, Q275, Q295, Q345, 08F, 08, 08AL, 08F, 10F, 10, HG5, DF08 SPHC, M8

Size:

LSAW, DSAW:

Outer Diameter: 406.4mm-1422mm(16”-56”)

Wall Thickness: 9.0mm-60mm

Length: 6mtr-18mtr

End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled,

Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE)

Packing: Bare or as customer required

Delivery time: 7-30day or as customer’s requirements

Loading port: Xingang (Tianjin) port or Shanghai port

Payment terms: T/T, L/C at sight or negotiate