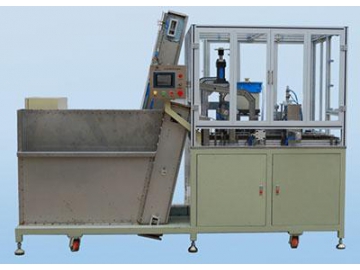

Aluminum Cap Washing Machine, CDDA Series

The CDDA series automatic aluminium cap washing machine has the function of washing, silicification, sterilization, and drying with higher efficiency of cleaning, but without any mechanical injury to the surface of aluminium caps. Shonly provides you with a variety of models of aluminium cap washing machine for the capacity of from 10,000 pcs to 200,000 pcs at a time. You will be suggested to select right models suitable for your product requirements.

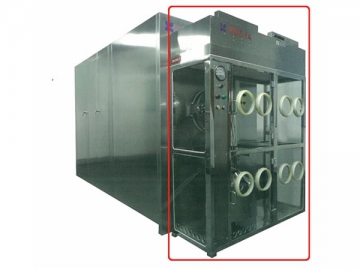

- Steam sterilization aluminium cover cleaning machine

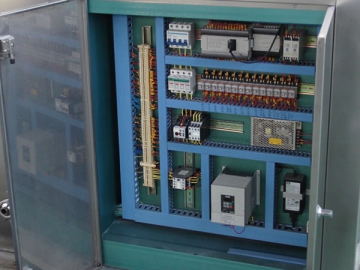

- Face of entrance of electric & water & air face of loading

- Face of loading back face

Each Cleaning Capacity: from 10,000 to 200,000 pcs

| Model CDDA- | | | | | | | | | | | |

| Cleaning quantity (pcs ) | 10,000 - 15,000 | 20,000 | 30,000 | 40,000 | 60,000 | 80,000 | 100,000 | 120,000 | 150,000 | 180,000 | 200,000 |

| Total power (kw) | 12.5 | 12.5 | 15.5 | 15.5 | 18 | 18 | 20.5 | 20.5 | 24 | 24 | 24 |

| Dimensional sizes (LxWxH mm) | 2030*1240*1820 | 2200*1240*1820 | 2160*1280*1880 | 2620*1280*1880 | 2850*1440*1940 | 2920*1540*2100 | 2980*1640*2160 | 2950*1740*2200 | 3150*1800*2300 | 2900*1900*2300 | 3150*1900*2300 |

| Machine weight (kgs) | 1450 | 1500 | 1600 | 1700 | 1950 | 2050 | 2200 | 2300 | 2450 | 2600 | 2700 |

Note: Take 20-ZB aluminium cover as a standard cleaning quantity

Main technical parameters of aluminum cap washing machineEach Cleaning Capacity: from 10,000 to 200,000 pcs

| Model CDDA- | | | | | | | | | | | |

| Cleaning quantity (pcs ) | 10,000-15.000 | 20,000 | 30,000 | 40,000 | 60,000 | 80,000 | 100,000 | 120,000 | 150,000 | 180,000 | 200,000 |

| Total power (kw) | 9 | 11.5 | 14.5 | 17 | 20 | 22 | 24 | 26.5 | 29 | 31.5 | 34 |

| Dimensional sizes (L x W x H mm) | 1935*1040*1770 | 1950*1040*1770 | 2495*1240*1840 | 2785*1240*1840 | 2675*1300*1880 | 2825*1300*1880 | 2810*1440*1980 | 2770*1580*1980 | 2800*1680*2000 | 2800*1780*2100 | 3050*1780*2100 |

| Machine weight (kgs) | 1300 | 1350 | 1450 | 1550 | 1700 | 1800 | 1950 | 2050 | 2250 | 2400 | 2500 |

Note: Put "OZ" before the standard model as ozone aluminium cover cleaning machine

Take 20-ZB aluminium cover as a standard cleaning quantity

Features

1. High level integrative equipment, without accessional electric operating counters.

2. Highly configured standard critical parts which adopt international famous brand.

3. Sensors of high precision cooperate with ideal software make the operation achieve perfect condition.

4. Small volume, large cleaning quantity.

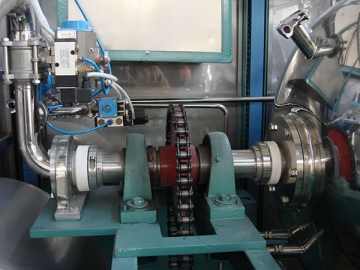

5. Simple structure, fast-joined device is used for pipeline connecting.

6. Can be disassembled from three sides, the maintenance is very convenient.

7. The temperature difference in the cavity is less than ±0.6℃ special cylindrical structure, the heat has homogeneous distribution.

8. Do no pollution to the internal cavity attributed to external mechanical seal device.

9. The doors of two different cleaning areas are isolated completely by mechanical gaseous lock and program-controlled electronic interlocking.

10. Transducer regulating speed makes easily adapted to the shift of technology requirements and rubbers stopper types.

11. On-line clarity detection makes the quality of cleaning easy to see, and achieve strict control.

12. The distance between the valves connected to the cavity and the cavity is less than 3D of the connecting pipeline’s diameter.

Features

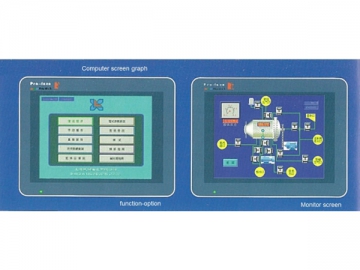

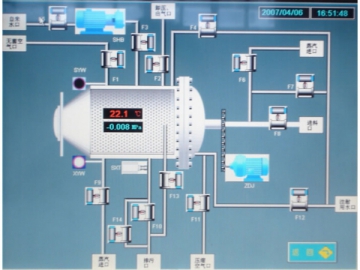

1. High degree of automatization: Colored LCD touch screen and Programmable Controller, truly achieve full automatic operation from feeding to discharging.

2. All the actuators have feedback signals, which can implement real-time monitoring, automatic alarm and remind the cause of malfunction as well as the obviation methods.

3. Four levels of password control, equipment hierarchical management and operation, to ensure legal operation and optimize the operating procedures.

4. Automatically memorize the operation of the last time, constant cleaning quality, eliminate factitious misoperation.

5. Automatically record and print, historical records can be referred to and printed.

6. FO value can be controlled to ensure the sterilization quality, conforming to the GMP standard and FDA standard.

7. Programs revisable, senior managers can input the four levels of password to adjust all technology parameters.

8. Several work flows (procedures) can be designed in advance.

9. Technology parameters such as time, temperature and pressure are revisable.

10. The equipment can accomplish all the process operations automatically dispense with manual assistant if choosing automatic running.

11. Acousto-optic alarm when public system lack items or served abnormally.

12. Multiplex protection for cavity hyper pressure.

13. Automatic protection of computer programs when power cut.

14. Original record reappearing and printing.

Technology

Features

Vacuum-removed bubbles

Once the system creates a vacuum, the pressure on the submerged rubber stopper changes, causing air bubbles around the rubber stopper to grow and burst. Dirt and other impurities near the rubber stopper are removed by the force.

Alternate impact of air and water currents

Compressed air impacts the submerged rubber stopper, deep cleaning the rubber stopper aided by instantaneous changes in hydraulic pressure. The rubber stopper is extruded and dirt is removed through vibration.

Technology Features

1. Apply the advanced method of "Vacuum removing bubbles" mixed with "impact of air and water" for rubber stoppers or aluminum covers cleaning.

2. Advanced principles for cleaning.

3. <cleaning structure of air currents and water currents mixed cleaning devices used for elastic objects> has got a national patent in 2000.

4. High cleaning efficiency, use less water.

5. Do no damage to the surface of the rubber stopper, high cleaning degree.

6.By the inspection for pharmaceutical production, the clarity of the rubber stoppers cleaned by this equipment conform to <Chinese Pharmacopoeia> standards.

7. Silicification processed at the temperature of above 80 to make rubber stoppers silicified homogeneously.

8. Automatically judge and adjust the standard sterilization values (F0 value) to ensure the equivalent sterilization effect strictly every time.

9. Vacuum drying or vacuum assistant electrical heat drying, has the feature of rapid, small energy consumption, low moisture, meet the requirements of all pharmaceutical technology.

10. The optional program and flexible process control can adjust the cleaning process at any moment, to achieve optimal cleaning effect.

Aluminium Cap Washers

Features

Turnover Unloading System

1.Advanced unloading pattern meets GMP, FDA, and CGMP requirements.

2.Unloading system capable of carrying out CIP and SIP.

3.Fully enclosed unloading effectively prevents contaminating stoppers through contact with the environment.

4.Easy to realize aseptic butt-joint transfer by αβ valve or by RABS system.

Back Door Take-out Structure

For large-scale stopper cleaners and aluminum caps cleaners, this structure makes disassembly easy and convenient when maintenance is needed.

RABS System

1.New method for aseptic unloading and transferring that meets GMP requirements.

2.Convenient stopper unloading and transfer, prevents contamination, and improves efficiency.

3.Easy cleaning, sterilization, and maintenance.

4.Economic.

5.Barrels or aseptic PE bags can be used to transfer stoppers. Automatic sealing of PE bag prevents contamination.

6.Online detection device keeps rubber stoppers sterile.