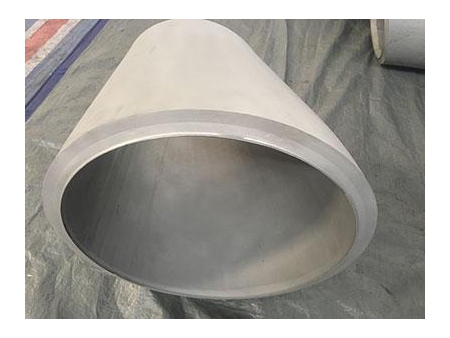

Pipe Reducer

As one type of industrial fittings, reducing pipe is mainly used for connection between two pipelines with different diameters. Generally, pipe reducers can be divided into concentric reducer and eccentric reducer. The former is often used on vertical pipelines, while the latter is usually installed on horizontal pipelines. Sometimes, flow rate can’t change two much when the flow increases or decreases in a pipeline. The reducer is perfect for this situation. It is able to effectively prevent cavitation when installed in the inlet of a pump. The reducer is also needed at the joint points of an instrument such as flow meter or control valve to coordinate with the instrument.

Outer Diameter

Seamless reducing pipe: 1/2"~32", DN15~DN800

Seamed reducing pipe: 6"~60" DN150~DN1500

Thickness

SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS, SCH5S, SCH20S, SCH40S, SCH80S. The largest thickness reaches 200mm

Standards

GB/T12459-2005, GB/T13401-2005, GB/T10752-2005

SH/T3408-1996, SH/T3409-1996

SY/T0609-2006, SY/T0518-2002 SY/T0510-1998

DL/T695-1999, GD2000, GD87-1101

HG/T21635-1987, HG/T21631-1990

ASME B16.9-2007, ASME B16.25-2007

MSS SP 75-2008, MSS SP 43-2008

CSA Z245.11-05-2005

EN10253-1-1999, EN10253-2-2007, EN10253-3-2008, EN10253-4-2008

DIN2616-1-1991, DIN2616-2-1991

BS1640-1-1962, BS1640-2-1962, BS1640-3-1968, BS1640-4-1968, BS1965-1-1963

GOST17378-2001

AFNOR NF A 49-289-1990, AFNOR NF A 49-170-1-1999, AFNOR NF A 49-170-2-2009, AFNOR NF A 49-170-3-2009, AFNOR NF A 49-170-4-2009

ISO3419-1981, ISO5251-1981

JIS B2311-2009, JIS B2312-2009, JIS B2313-2009

Raw Materials

Carbon steel: ASTM/ASME A234 WPB-WPC

Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low-temperature steel: ASTM/ASME A402 WPL 3-WPL 6

High-performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Production Process

Bending --- Extruding --- Pushing --- Mould Pressing --- Cold Machining or Hot Forming

Application

The product is widely used in many areas such as power generation plant, petroleum industry, natural gas system, chemical industry, shipbuilding industry, heating system, paper-making industry, metallurgy industry, etc.