PPR Stabi Composite Pipes and Fittings

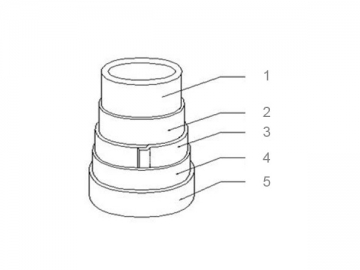

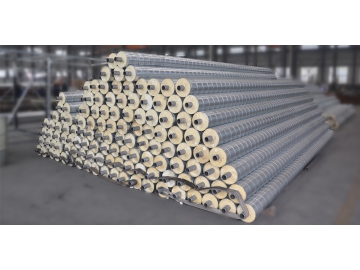

The PPR Stabi composite pipes and fittings are manufactured from PP-R material and include a layer of perforated aluminum barrier. The aluminum layer is organically bond to the inner PP-R layer using thermal bonding technique under high temperature and pressure and then coated with a layer of PP-R again. The multilayer composite pipe comes with typically five layers.

Application Fields of the PPR Stabi Composite Pipes

• Heating system by hot water, central air conditioning and heating radiator;

• Indoor and outdoor exposed piping system;

• Outdoor water supply pipe networks, such as solar energy pipe network

1: Internal Pipe

2: inner rubber protective layer

3: aluminum layer

4: outer rubber protective layer

5: outer cladding layer

2: common PPR Pipe

Features

1. The PP-R stabi pipes offer all the advantages of PP-R pipes.

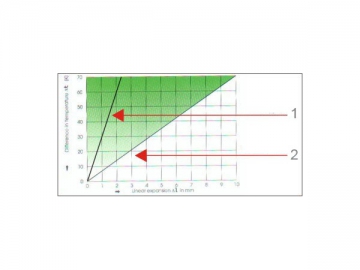

2. They also come with small linear expansion coefficient that is only 1/5 of that of common PPR pipes, close to that of metal pipes. Comparison diagram is shown below.

3. The composite pipes are suitable for exposed installation where they will not deform, thus reducing supports and ensuring eye-catching appearance.

4. Our PPR Stabi composite pipes and fittings feature more outstanding resistance to high temperature and pressure as compared with common PPR pipes and fittings.

5. They provide strong performance in resisting UV and scratch, without oxygen permeation and light transmittance, thus restraining algae growth.

6. Reliable connection delivers high safety.

| Item | Spec.(mm) | Pack(m/bunch) |

| 20×3.4 | 160 | |

| 25×4.2 | 120 | |

| 32×5.4 | 72 | |

| 40×6.7 | 48 | |

| 50×8.3 | 32 | |

| 63×10.5 | 20 | |

| 75×12.5 | 12 |

| Item | Spec.(mm) | Pack(m/bunch) |

| 20×2.8 | 160 | |

| 25×3.5 | 120 | |

| 32×4.4 | 72 | |

| 40×5.5 | 48 | |

| 50×6.9 | 32 | |

| 63×8.6 | 20 | |

| 75×10.3 | 12 | |

| 90×12.3 | 8 | |

| 110×15.1 | 8 |

| Item | Spec.(mm) | Pack(m/bunch) |

| 20×2.3 | 160 | |

| 25×2.8 | 120 | |

| 32×3.6 | 72 | |

| 40×4.5 | 48 | |

| 50×5.6 | 32 | |

| 63×7.1 | 20 | |

| 75×8.4 | 12 | |

| 90×10.1 | 8 | |

| 110×12.3 | 8 |

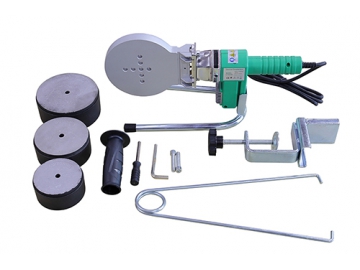

Tools

Tools for processing PPR Stabi composite pipes include manual and electric peeling tools which provide reasonable cutting depth and size and therefore avoid central stress concentration after welding.

Welding machine is outfitted with professional die heads that enable the outer coating of the pipe to be welded into the fittings by 2-3mm.

-

PPR-AL-PPR Pipe Welding Machine and Die Heads -

Die Head Combination -

Electric

Peeling Tool -

Electric Peeling Tool Heads -

Peeling Tool Accessory -

Manual Electric Peeling Tool