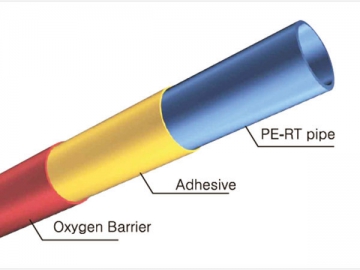

PERT Pipes with EVOH (for Underfloor Heating)

The PE-RT pipes with oxygen barrier are designed for underfloor heating system. They are co-extruded with 3 or 5 layers of materials, giving it significant strength. For 3-layer tubing, the inner, sandwich and outer layer are respectively PE-RT, adhesive and oxygen barrier; for the 5-layer tubing for an example, the inner and outermost layers are PE-RT, and sandwich layer is an EVOH oxygen barrier. These layers are bond by hot melt adhesives.

With all advantages of PE-RT pipes, this floor heating pipe can effectively prevent oxygen permeating into the heating system and thereby eliminate bacteria growth inside the pipes to ensure clean water and better sanitation, as well as protect the metal parts in the system from oxidization to ensure a much longer service life.

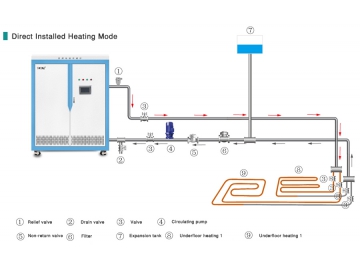

Applications

The PERT Tubing with oxygen barrier is more flexible and easier to install than other piping materials in radiant heating and hydronic heating systems.

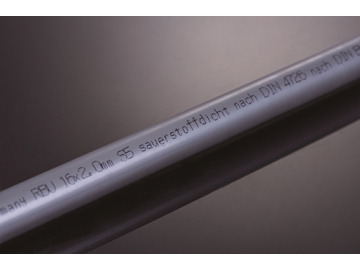

| Product Name | Item Number | Series | Specifications | Package (m/ coil) |

| PE-RT pipe with oxygen barrier | 240005001 | S5 | 20×2.0mm | 220 |

| 240005002 | 25×2.3mm | 110 | ||

| 240005003 | 32×2.9mm | 55 | ||

| 240004001 | S4 | 20×2.3mm | 220 | |

| 240004002 | 25×2.8mm | 110 | ||

| 240004003 | 32×3.6mm | 55 | ||

| 240004001 | S3.2 | 20×2.8mm | 220 | |

| 240004002 | 25×3.5mm | 110 | ||

| 240004003 | 32×4.4mm | 55 |

Kingbull PE-RT Pipes

1. We use reliable quality PE-RT materials without addition of recycled materials. At present, the raw materials that we use for producing PE-RT pipes come with the up to standard creep rupture curve. They include PE-RT from world famous manufacturers such as Dow, Basel, LG and SK.

2. Original Battenfeld PE-RT pipe extrusion line with KIV forced feed system and advanced BM barrier screw enables us to realize high speed extrusion at low speed and retaining complete performance.

3. Advanced cooling and sizing system and technique account for high production speed, stable molding, high dimensional accuracy and stability and great appearance.

4. Computer controlled laser diameter measuring instrument and laser thickness measuring instrument guarantee high size stability.

5. 100% air pressure test (2MPa, 2min) completely eliminate the potential risk of underfloor installation.

6. Complete set of cutting edge test equipment make it happen.

7. As the largest and the earliest manufacturer of PE-RT pipes in China, we can product 30t PE-RT pipes a day. Calculating by dn20*S5, we have a production capacity of about 250,000m/d.

8. We enforce rigorous three-class quality control and run standard quality management system, ensuring reliable QC.

9. Advanced ERP system and perfect pipe coding information and production operating record system make production of the pipes traceable.

Kingbull PE-RT Pipes with Oxygen Barrier

1. This underfloor heating pipe uses top quality EVOH imported from Kuraray Japan

2. Our PE-RT pipes with oxygen barrier are manufactured in strict accordance with industry standards.

(1) PE-RT Layer

(2) Adhesive Layer

(3) Oxygen Barrier Layer

3. Thanks to our self developed peeling tool, we can carry out safe heat fusion.

4. 3-Layer PE-RT pipes come with better oxygen barrier effect. Outermost layer of 5-layer PE-RT pipes is a barrier for water evaporation, so the oxygen barrier layer has high humidity that will weaken oxygen barrier effect.

| Humidity | 65% RH | 85%RH | 90%RH |

| FP104B | 3.0 | 23 | 48 |

| EP105B | 16 | 32 | 38 |