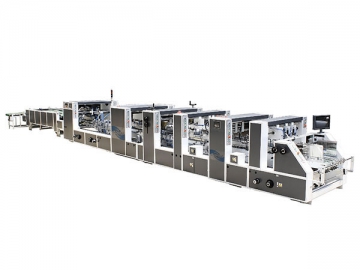

Multifunctional Folder Gluer (For 4 and 6 Corner Cartons)

FH-1450-6 Automatic Multifunctional Folder Gluer

Introduction

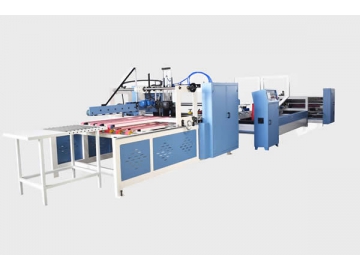

Our FH-1450-6 automatic multifunctional folder gluer is mainly used for manufacturing medium-sized packaging, such as 300g-800g paperboard, 1mm-10mm two-fold corrugated paper, and packaging boxes with four-fold crash lock bottom, four corners and six corners. This folder gluer for sale can also be applied to the die cutting, watermark and slotting of the mounted and framed corrugated paper with five layers, two folds, four folds, crash lock bottom, four corners and six corners.

Having diverse functions and easy operation, our automatic folder gluer is equipped with unique locator for paper position, secondary pressure line device, modifying device and continuous conveyor. Our multifunctional folder gluer is installed with touch screen terminal, PLC operating system, remote control system, electric panel, high-power servo motor, etc. Beside, its transmission structure uses the durable gearbox; and its pressure is adjusted by pneumatic control.

Featuring high stability and efficiency, our multifunctional folder gluer can fully meet the need for user-friendly operation. This carton folder gluer has the specific functions as the follows:

1. Numerically adjusting the position of guide plate and the size of box;

2. Intelligently saving the location of the finished products and memorizing the data for next production; it can save up to 20 sets of data.

Technical Parameters of Multifunctional Folder Gluer

Specifications of FH-1450-6

Applicable paper: white cardboard (300g -800g), mounted and framed corrugated paper with five layers

Paper feeding: automatic and continuous

Gluing speed (Max.): 180m/min

Box width: 400mm-1,450mm

Dimension (L×W×H/M): 18m × 2.7m × 2.2m

Glue type: Solute glue

Total weight (approx.): 16T

Power supply: about 40Kw

| Type of Gluing | One Side | Crash Lock Bottom | Both Sides | Four Corners | Six Corners |

| Max. (mm) | 1,450 ×1,000 | 1,300 ×1,000 | 1,000 ×900 | 1,300 ×900 | 1,250 ×800 |

| Min. (mm) | 400 ×200 | 500 ×250 | 480 ×180 | 500 ×350 | 700 ×400 |

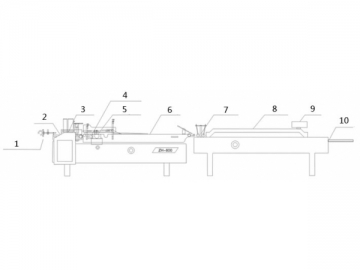

Key Sections of Multifunctional Folder Gluer

Feeder, Gluing unit, Crash lock bottom, Folding unit, Trombone, and Conveyor

1.Feeder

The multifunctional folder gluer's paper feed section consists of 9 induced draft belts with the width of 50mm, 10mm metal plate for the horizontal adjustment of width, and embossing wheels to guide the pulley belt.

Guard plates are provided at the left and the right sides for the moving product; the equipped three paper knives can regulate the asymmetric length according to the real situation; the air-suction device can help the motor to continuously and automatically supply paper quickly and easily.

Paper can be stacked up to the height of 330mm; the pneumatic pressure can ensure the stable and smooth paper feeding of corrugated paper; the operator can manipulate the switch of paper feeding in any operating area.

2.Gluing unit

The multifunctional folder gluer's gluing unit has three-belt structure. The upper belt is the main drive to ensure stable and smooth paper conveying; all the bottom gluing drums can be assembled and dissembled; there are gluing drums with large capacity fitted on the left and right side for the use according to actual situation; having adjustable capacity, the gluing drums are stable and have easy maintenance.

The provided gluing rollers have the thickness of 5mm-20mm and are selectable according to your special requirements; the gluing drums are made of solid and durable alloy stainless steel; it is completed with four sets of crash locking mechanisms.

The bottom belt has the thickness of 50mm and the upper belt 30mm. The pneumatic pressure makes the belts move to accommodate cardboards with different thicknesses.

3. Crash lock bottom

The multifunctional folder gluer's crash lock bottom section has three-belt structure, of which the upper belt is the main drive to ensure stable and smooth paper conveying. There are two high-power servo motors of Yaskawa to complete the anti-lock function. The glue sprayer from Taiwan has three photoelectric spraying guns. The servo control works by regulating the PLC controller and the touch screen terminal.

The parameters can be adjusted easily and quickly. You can simply enter the parameter on the touch screen to achieve the optimal efficiency. The speed can be detected and tracked via the encoder, which can ensure the servo's speed conforms to the speed of main motor.

4. Folding unit

The multifunctional folder gluer's folding unit consists of three-belt structure and the upper belt is the main drive to ensure stable and smooth paper conveying. We adopt the combination of 80mm bottom belts and 80mm elbow belts; the left and the right sides have the second fold line of 180°, fully integrating with the fourth fold line of 180°.

The guide wheels at the left and right can not only adjust according to different locations, but also smoothly cooperate with the folding box; the bearing at the bottom supports the correct operation of the belt. As the speed of the elbow belt is adjustable, the speed of elbow belts at the left and right can be individually adjusted to prevent the appearance of bell-mouthed box.

5.Trombone

The multifunctional folder gluer's trombone section is equipped with specific device to not only correct the error in the folding process; but also automatically and continuously accumulate boxes and transport them neatly to the conveyor. The length of the upper belt and bottom belt can be adjusted.

We also adopt the automatic electric counter, air compressed system and trombone transmission system. In addition, the pressure roller is adaptable to different box types and printing materials, helping to make more perfect boxes.

6. Conveyor

Composed of a set of rubber wheels, the multifunctional folder gluer's conveyor section has separate transmission structure at the top and the bottom. The imported belt is moderately soft and will not bruise the finished products; the entire conveyor can move forward and backward.

The conveyor provides balanced pressing and neat delivery to protect the products' perfect quality.

The conveyor operates according to the main motor and cooperates with the phototube. The manual operation on the mode and speed is also available.

Main Parts and Accessories of Multifunctional Folder Gluer

1) Main motor is from Teco (Taiwan);

2) The frequency converter is from Panasonic (Japan);

3) The human-machine interface is from HITECH (Taiwan);

4) The timing synchronization wheel and belt are from OPTIBELT;

5) The bearings are from NSK and KOYO (Japan) and BEM (Germany);

6) The spindle is made of hard chrome steel bar from Taiwan;

7) The machine's body panels are made of international # 25mm thick iron plate, which have been treated with the hot and cold adjustment process;

8) The conveyor belt is a special belt from Habasit;

9) The flat belt is from NITTA , the world famous Japanese brand;

10) The PLC is from FATEK (Taiwan); and the electrical components are all from Mitsubishi and other famous brand in Japan;

11) The fastening bolts are inner hexagon screws in the class of Taiwan 12.9;

13) The servo motor is from YASKAWA (Japan);

14) The glue sprayer has three photoelectric spraying guns.

Appendix: Standard Fittings of Multifunctional Folder Gluer

Operating toolbox and tools: 1 set

5.5HP air compressor: 1 set

Photoelectrical control counter (automatic): 1 set

Handles: 1 short and 1 long

Foot pads: 28 pieces

Horizontal pipe: 10m

Combination of crash lock bottom: 4 sets

aluminum sliding sleeve: 8 (two of them are mounted on the machine)

Anti-lock accessories: 7 sets

Sliding sleeve rack: 8 sets

Crash lock bottom: 8 pieces

Displayer: 1 piece (mounted on the machine)