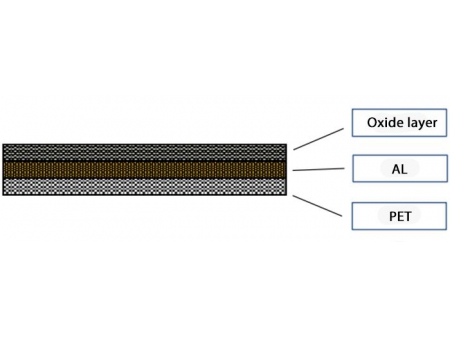

Aluminum Metallized PET Film

Request a Quote

Vacuum metallized polyester film

- Total thickness: (10μm to over 100μm) ±3μm

- PET layer thickness: (≥1.6μm) aluminum layer (≥0.1μm)

- Tensile strength: ≥30Mpa

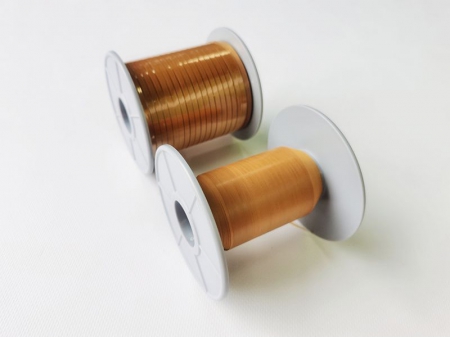

- Width: 0.5mm to 990mm

- Elongation rate: ≥30% minimum

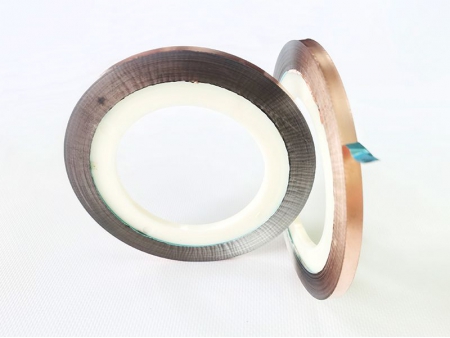

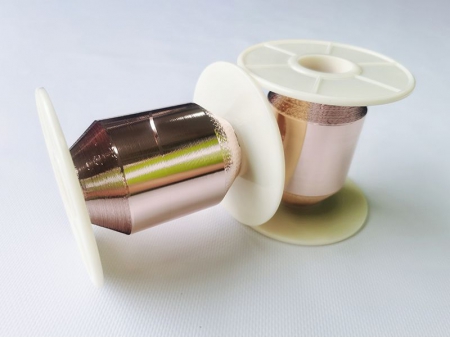

- Packaging: rolls(D30), sheets, 76mm removable rolls, inverted cone packaging

Aluminum metallized PET film involves vacuum depositing aluminum onto the film's surface, which boasts a high dielectric constant, excellent insulation resistance, thermal insulation, and strong tensile properties.

Features

- Suitable for uneven surfaces

- Offers high flexibility

- Easy to use

Applications

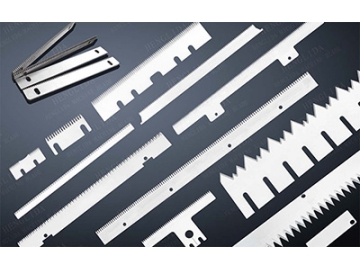

- Flame retardant materials

Flame retardant tapes and films employs a flame-retardant backing, preventing contact between flammable substances (such as motor oil, lubricants, etc.) and high-temperature components, thereby reducing the risk of fire incidents in vehicles, ships, aircraft, and more. The inner side of the flame-retardant tape typically features pressure-sensitive adhesive, allowing it to wrap around pipes, valves, exhaust systems, turbochargers, etc., ensuring strong adhesion, while the flame-resistant backing on the reverse side enhances flame-retardant and insulation capabilities. - Thermal conductive materials

Insulation tape for sealing joints in pipes and ventilation ducts, preventing energy and heat loss, and improving energy efficiency.

EMI shielding tape for reducing EMI interference in electronic products.

Pipeline protection tape for safeguarding pipes against corrosion, wear, or damage. - Data transmission cable

Total Thickness: (10μm to over 100μm) ±3μm

Non-Metal Base Layer Thickness: (≥1.6μm)

Metal Layer Thickness: (≥0.1μm)

Tensile Strength: ≥30Mpa

Width: 0.5mm to 990mm

Elongation Rate: ≥30% Min

Heat Sealing Strength: 3.5KG - EMI shielding

Effective EMI shielding materials require good electrical conductivity and magnetic permeability. Common materials used for electromagnetic shielding include metals, carbon-based composites, intrinsically conducing polymers, silicone, foams, films, and fabrics, among others.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos