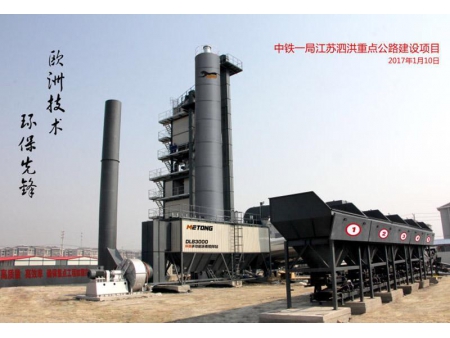

Environmental Multi-function Asphalt Mixing Plant

Features

(1) Versatility: With the multi-functional connector, the asphalt mixing plant can be equipped with environmental protection facilities, hot recycling equipment, cold recycling equipment and other equipment, and process colored asphalt and various additives. It can be slightly retrofitted and become a two-in-one mixing plant for bituminous mixture and cement concrete.

(2) Economy: The high-precision measurement ensures the lowest production cost. The most advanced burner minimizes the fuel consumption. A large number of maintenance-free structures and parts reduce the maintenance cost for the user.

(3) Reliability: The advanced technology and the high-level configuration ensure a stable and reliable running.

(4) Modular structure design: The plant can move quickly to another site. It facilitates the transportation, the installation and the commissioning.

(5) Safety and comfort: The space structure is designed according to ergonomic design. The asphalt mixing plant is nice, comfortable and convenient, while safe and reliable.

| Model | DLB2000 | BLB3000 | BLB4000 |

| Rated productivity(t/h) | 160 | 240 | 320 |

| Total installed capacity(KW) | 380 | 570 | 734 |

| Fuel consumption | ≤6.0 (standard condition) | ||

| Capacity of finished product silo (t) | 60 | 120 | 160 |

| Dust emission concentration | ≤20mg/Nm³, Ringelmann emittance≤ Class I | ||

| Measuring accuracy | Static | Aggregate: ±0.3% Powder: ±0.2% Asphalt: ±0.15% | |

| Dynamic | Aggregate: ±1.5% Powder: ±1.0% Asphalt: ±1.0% | ||

| Bitumen-aggregate ratio | ≤±0.1% | ||

| Asphalt tank quantity | 2×50000L | 3×50000L | 4×50000L |

| Heavy oil tank quantity | 1×30000L | 1×50000L | 1×50000L |

| Diesel tank | 1×12000L | 1×12000L | 1×12000L |

| Thermal oil boiler | 600,000 kilocalorie | 800,000 kilocalories | 800,000 kilocalories |

| Model | DLB2000 | DLB3000 | DLB4000 |

| Total installed capacity | 380KW | 570KW | 734KW |

| Max. power of a single machine | 110KW | 160KW | 185KW |

| Transformer | ≥500kV/A | ≥630kV/A | ≥800kV/A |

| Voltage of power supply | 380V±5% | ||

| Frequency of power supply | 50±0.1Hz | ||

| Transmission system | Three-phase four –wire system | ||

| Wire diameter of cable | 2×(3×150 35)copper core cable | 2×(3×185 50)copper core cable | 2×(3×240 70)copper core cable |

| Cable length | The distance between the power distribution cabinet of the transformer and the power switchgear of the control room. The protector must be equipped for the incoming; the total length of incoming cable should not exceed 300 meters. | ||

| Ground resistance | ≤4Ω | ||

| Ground connection | TM-S neutral-to-case connection | ||

| Lightning arrester | Apply to local meterological department for installation according to local climatic conditions and national standards to the local meteorological department | ||

Note: For the mixing plant equipped with coal burner as its main burner, the power should be 1 level higher (for example, DLB3000 coal burner should be configured according to DLB4000)

Remark: The main cable must be copper cable in accordance with the national standard. If the aluminum cable is used, the wire diameter should be increased. For underground laying, armored cable should be chosen and the protective measures should be carried out.

Zhejiang Metong Road Construction Machinery Co.,ltd.

Add.: Room 2201, Building 2, Qiantang Aviation Mansion, No.66, Shimin Street, Hangzhou, China

Zip Code: 310009

Tel.:

Fax: 86-571-87815510

Email:

Contact person: Ms. Yuki

Whatsapp: 86-18268042003

Mobile: 86-18268042003