Military Grade Heat Shrink Marker

Request a Quote

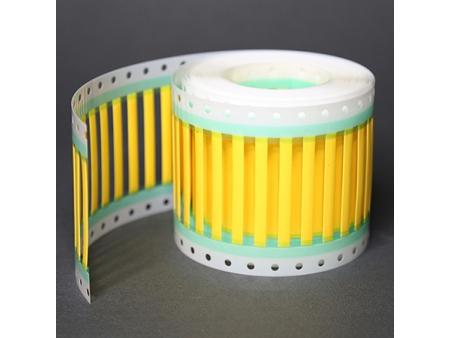

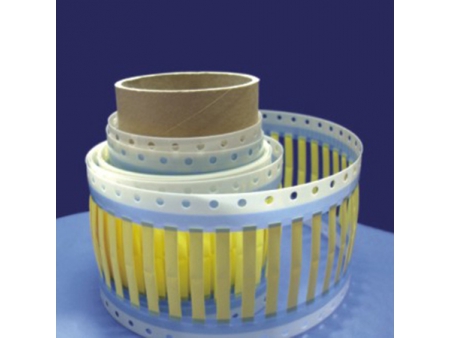

CYG-MT (AMS)

Heat Shrinkable Identification Sleeve for Wire & Cable Management

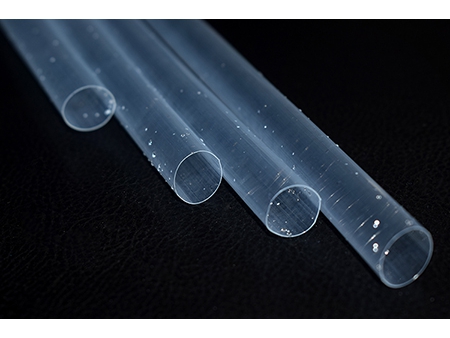

- Material: Cross-linked modified fluorine polymer

- Shrink ratio: 2:1 / 3:1

- Compliant with "RoHS" environmental standards

- Flexible, temperature-resistant, and high flame-retardant

- Superior printing performance for long-lasting identification

Applications

- Our military grade heat shrink marker is the ideal solution for a wide range of electronic applications. Its high flame-retardant properties and superior electronic insulation and mechanical protection make it ideal for insulating and identifying wires, cables, and terminals in demanding environments.

Features

- Compliant with "RoHS" environmental standards

- Flexible, temperature-resistant, and high flame-retardant

- Superior printing performance for long-lasting identification

- Meets GJB 7277-2011 standards

| Properties | Test Method | Typical Value | |

| Operating temperature (℃) | - | -55~135 | |

| Water absorption (%) | 23℃/24h | ≤0.5 | |

| Longitudinal change (%) | - | -5~ (5 2:1) -20~ (5 3:1) | |

| 2% Scan modulus (MPa) | - | ≤172 | |

| Tensile strength (MPa) | 500mm/min | ≥10.4 | |

| Ultimate elongation (%) | 500mm/min | ≥300 | |

| After aging 175℃/168h | Appearance | unidirectional rubbing for 50 times | the print is clearly visible |

| Ultimate elongation (%) | 500mm/min | ≥100 | |

| Insulation and voltage withstand | 2500V/60s | No breakdown | |

| Dielectric strength (kV/mm) | - | ≥ 19.7 | |

| Volume resistivity (Ω·cm) | - | ≥1014 | |

| Fluid resistance 23℃/24h | Tensile strength (MPa) | 500mm/min | ≥6.9 |

| Dielectric strength (kV/mm) | - | ≥15.8 | |

| Appearance | Unidirectional rubbing for 20 times | the print is clearly visible | |

| Heat shock | 225℃/4h | No dripping, no flowing, no cracking; After unidirectional rubbing for 50 times, the print is clearly visible; | |

| Printing durability | Rubbing for 30 times | the print is clearly visible | |

| Color stability | 175℃/24h | No fading | |

| Low temperature flexibility | -55℃/4h | No cracking | |

| Copper corrosion | 175℃/16h | No corrosion | |

| Flammability | - | Self-extinguishing within 60s | |

| Cold & heat shock test | -55℃, 135℃ | Ultimate elongation ≥100%; After unidirectional rubbing for 50 times, the print is clearly visible | |

| Salt spray test | GJB 150.11 | Ultimate elongation ≥100%; After unidirectional rubbing for 50 times, the print is clearly visible | |

| Damp heat test | GJB 150.9 | Ultimate elongation ≥100%; After unidirectional rubbing for 50 times, the print is clearly visible | |

| Fungal test | GJB 150.9 | Better than class 1 | |

Shrink Ratio: 2:1

| Size | As Supplied (mm) | After Recovery (mm) | |

| Minimum Inside Diameter | Maximum Inside Diameter | Wall Thickness | |

| Ø1.6 | 1.6 | 0.8 | 0.40±0.08 |

| Ø2.4 | 2.4 | 0.8 | 0.50±0.10 |

| Ø3.2 | 3.2 | 1.0 | 0.50±0.10 |

| Ø4.8 | 4.8 | 1.6 | 0.50±0.10 |

| Ø6.4 | 6.4 | 2.1 | 0.55±0.10 |

| Ø9.5 | 9.5 | 3.2 | 0.60±0.10 |

| Ø12.7 | 12.7 | 4.2 | 0.60±0.10 |

| Ø19.1 | 19.1 | 6.4 | 0.62±0.10 |

| Ø25.4 | 25.4 | 8.5 | 0.70±0.10 |

| Ø38.1 | 38.1 | 19.1 | 0.64±0.10 |

| Ø50.8 | 50.8 | 25.4 | 0.70±0.10 |

| Ø76.2 | 76.2 | 38.1 | 0.80±0.15 |

Note: Custom sizes are available upon request.

Related products

Send Message

Other Products