Cable Coil Shrink Wrapping Machine

Request a Quote

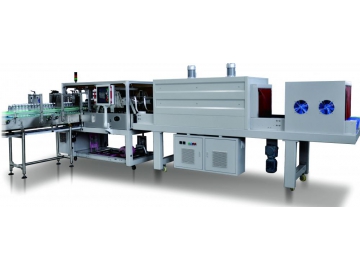

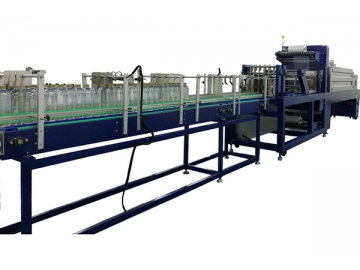

Cable packaging machine with heat shrink tunnel

Efficiently package your cable coils with our Cable Coil Shrink Wrapping Machine.

Our fully enclosed cable coil shrink wrapping machine is specifically designed for the packaging of wires and cables. After being cut to size, the cables are automatically fed into the machine via a conveyor belt for precise and efficient heat shrink packaging.

Specifications

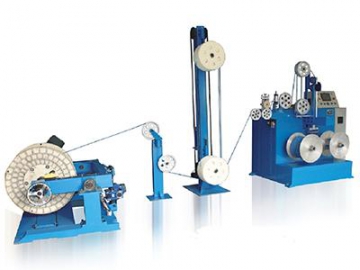

| Model | C0836 | C1246 | C1860 | C2060 | C2480 |

| Rotating speed(rpm) | 1000 | 800 | 200 | 150 | 100 |

| Outer diameter of coils(mm) | Ø180 - 360 | Ø200 - 460 | Ø200 - 600 | Ø220 - 600 | Ø300 - 800 |

| Inner diameter of coils(mm) | Ø120 - 200 | Ø140 - 220 | Ø180 - 250 | Ø180 - 250 | Ø250 - 320 |

| Height of coils(mm) | 40 - 80 | 50 - 100 | 60 - 180 | 60 - 200 | 80 - 240 |

| Wrapping material | PVC, PE and etc. | ||||

| Automatic stacking and palletizing system | Optional | Optional | Optional | Optional | Optional |

Features

- The HP300 wrapping machine utilizes anti-stick and high-temperature alloy "L" type sealing knife to make sure the sealing is neat and free of crack, coke and smoke;

- The sealing knife is plated with Teflon non-stick layer, so the film will not stick on the knife;

- After sealing and cutting, the HP300 wrapping machine automatically transfers the coils to the heat shrinking machine by the conveyor belt for shrink packaging;

- Conveyor belt tension and conveying time can be adjusted to ensure stable belt tension so that the coil can be smoothly fed into the shrink bag;

- This wrapping machine adopts double-layer insulation device to prevent heat loss and reduce energy consumption;

- There is a fan in the heat shrink machine, and the heat source can be evenly distributed to all parts of the furnace;

- The temperature in the heat shrinking machine is about 150-200 ℃, which can be adjusted;

- All parts are equipped with safety guards and emergency stop devices to protect the operator.

- The HMI and PLC control system enables easy modification, storage, and adjustment of wire diameter, line speed, and other process parameters through the user-friendly touchscreen interface.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos