Heat Shrink Busbar Tubing

Request a Quote

CYG-BT

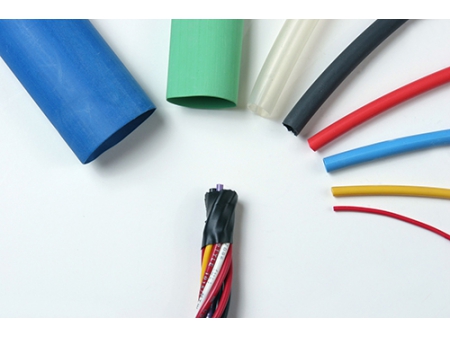

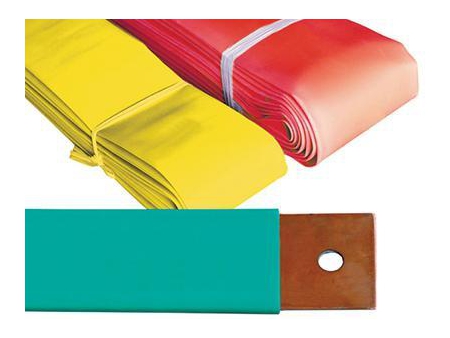

Insulation tubing for busbar protection

- Material: Cross-linked modified polyolefin

- Shrink ratio: 2.5:1

- Environmentally friendly and low smoke, our product meets RoHS environmental standards.

- Exhibits superior insulation performance, ensuring ideal protection for your busbars.

Applications

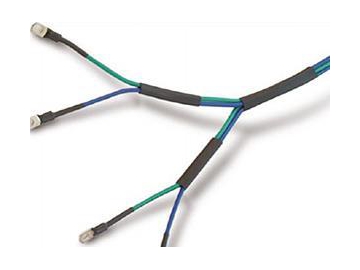

- Our busbar tubing finds wide applications in the field of busbar insulation and protection in both high and low voltage switchgear systems. It effectively prevents accidents caused by contact with live busbars.

- By avoiding contact between small animals and conductive elements, our tubing reduces the risk of short circuits and discharge faults.

- Our busbar tubing also safeguards against corrosion, pollution, and flashovers. Furthermore, it enhances insulation capabilities, reduces spacing requirements, and facilitates the compact design of switchgear systems.

Features

- Environmentally friendly and low smoke, our product meets RoHS environmental standards.

- Exhibits superior insulation performance, ensuring ideal protection for your busbars.

- Demonstrates superior toughness, withstanding various environmental conditions.

- Minimum shrinkage temperature: 110°C.

| Properties | Test Method | Typical Value |

| Tensile strength (MPa) | GB/T1040 | ≥8.0 |

| Ultimate elongation (%) | GB/T1040 | ≥300 |

| Heat aging | - | - |

| Tensile strength after aging (MPa) | GB/T1040, GB/T7141 | ±20 |

| Ultimate elongation after aging (%) | GB/T1040, GB/T7141 | ±20 |

| Radial shrinkage (%) | ASTMD2671 | ≥50 |

| Longitudinal change (%) | ASTMD2671 | ±20 |

| Eccentricity (%) | UL224 | ≤30 |

| Heat shock (160℃/4h) | JB7829 | No cracking, no flowing |

| Low temperature resistance (-40℃) | - | No cracking |

| Flammability (oxygen index 0.1) | GB/T2406 | ≥28 |

| Power frequency withstand voltage (kV/mm) | GB/T1408.1 | 2-95 |

| Dielectric strength (kV/mm) | GB/T1408.1 | ≥20 |

| Volume resistivity (Ω·cm) | GB/T1410 | ≥4.3×10 14 |

| Hardness (shore A) | GB 2411 | ≤90 |

| Properties | Unit | Performance | |||

| 1kV | 10kV | 20kV | 35kV | ||

| Power frequency voltage test | kV | 2 | 42 | 50 | 95 |

| lightning impulse voltage test | kV | 4 | 75 | 95 | 185 |

1kV Busbar Protection Heat Shrink Tubing

| Size | Applicable Busbar Width | As Supplied (mm) | After Recovery (mm) | Packaging (m/reel) | ||

| Inside Diameter | Wall Thickness | Inside Diameter | Wall Thickness | |||

| 1kV WMPG 30/15 | 30 | 31.5±1.0 | 0.45±0.15 | ≤15.0 | 0.95±0.15 | 50 |

| 1kV WMPG 35/18 | 35 | 36.5±1.5 | 0.45±0.15 | ≤18.0 | 0.95±0.15 | 50 |

| 1kV WMPG 40/20 | 40 | 41.5±1.5 | 0.50±0.15 | ≤20.0 | 0.95±0.15 | 50 |

| 1kV WMPG 45/23 | 45 | 46.5±1.5 | 0.50±0.15 | ≤23.0 | 1.00±0.15 | 25 |

| 1kV WMPG 50/25 | 50 | 51±2.0 | 0.50±0.15 | ≤25.0 | 1.00±0.15 | 25 |

| 1kV WMPG 60/30 | 60 | 60±3.0 | 0.55±0.20 | ≤30.0 | 1.00±0.15 | 25 |

| 1kV WMPG 65/33* | 65 | 65±3.0 | 0.55±0.20 | ≤33.0 | 1.10±0.20 | 25 |

| 1kV WMPG 70/35 | 70 | 70±3.0 | 0.55±0.20 | ≤35.0 | 1.10±0.20 | 25 |

| 1kV WMPG 75/38* | 75 | 75±3.0 | 0.55±0.20 | ≤38.0 | 1.15±0.20 | 25 |

| 1kV WMPG 80/40 | 80/100 | 80±3.0 | 0.55±0.20 | ≤40.0 | 1.20±0.20 | 25 |

| 1kV WMPG 85/43* | 80/100 | 85±3.0 | 0.55±0.20 | ≤43.0 | 1.20±0.20 | 25 |

| 1kV WMPG 90/45 | 100 | 90±4.0 | 0.55±0.20 | ≤45.0 | 1.20±0.20 | 25 |

| 1kV WMPG 100/50 | 100/120 | 100±4.0 | 0.60±0.20 | ≤50.0 | 1.20±0.20 | 25 |

| 1kV WMPG 120/60 | 150 | 120±4.0 | 0.65±0.20 | ≤60.0 | 1.30±0.20 | 25 |

| 1kV WMPG 150/75 | 180 | 150±4.0 | 0.65±0.20 | ≤75.0 | 1.30±0.20 | 25 |

| 1kV WMPG 180/90 | MAX | 180±4.0 | 0.70±0.20 | ≤90.0 | 1.46±0.20 | 25 |

| 1kV WMPG 210/105* | MAX | 210±4.0 | 0.70±0.20 | ≤105 | 1.46±0.20 | 25 |

| 1kV WMPG 230/115* | MAX | 230±4.0 | 0.70±0.20 | ≤115 | 1.46±0.20 | 25 |

| 1kV WMPG 250/125* | MAX | 250±5.0 | 0.70±0.20 | ≤125 | 1.46±0.20 | 25 |

| 1kV WMPG 300/150* | MAX | 300±5.0 | 0.70±0.20 | ≤150 | 1.46±0.20 | 25 |

10kV Busbar Protection Heat Shrink Tubing

| Size | Applicable Busbar Width (square/round) | As Supplied (mm) | After Recovery (mm) | Packaging (m/reel) | ||

| Inside Diameter | Wall Thickness | Inside Diameter | Wall Thickness | |||

| 10kV WMPG 15/8 | 15/12 | 15±0.8 | 1.20±0.30 | ≤8.0 | 2.1±0.30 | 25 |

| 10kV WMPG 20/10 | 20/15 | 20±0.8 | 1.20±0.30 | ≤10.0 | 2.1±0.30 | 25 |

| 10kV WMPG 25/12 | 25/18 | 25±0.8 | 1.20±0.30 | ≤12.5 | 2.1±0.30 | 25 |

| 10kV WMPG 30/15 | 30/20 | 30±0.8 | 1.20±0.30 | ≤15.0 | 2.1±0.30 | 25 |

| 10kV WMPG 30/18 | 35/25 | 36±1.0 | 1.20±0.30 | ≤18.0 | 2.1±0.30 | 25 |

| 10kV WMPG 40/20 | 40/30 | 40±1.0 | 1.20±0.30 | ≤20.0 | 2.3±0.30 | 25 |

| 10kV WMPG 50/25 | 50/35 | 50±2.0 | 1.20±0.30 | ≤25.0 | 2.3±0.30 | 25 |

| 10kV WMPG 60/30 | 60/45 | 60±3.0 | 1.20±0.30 | ≤30.0 | 2.3±0.30 | 25 |

| 10kV WMPG 65/33* | 65/45 | 65±3.0 | 1.20±0.30 | ≤33.0 | 2.3±0.30 | 25 |

| 10kV WMPG 70/35 | 70/50 | 70±3.0 | 1.20±0.30 | ≤35.0 | 2.3±0.30 | 25 |

| 10kV WMPG 75/38* | 75/50 | 75±3.0 | 1.20±0.30 | ≤38.0 | 2.3±0.30 | 25 |

| 10kV WMPG 85/43* | 80/55 | 80±3.0 | 1.20±0.30 | ≤40.0 | 2.3±0.30 | 25 |

| 10kV WMPG 80/40 | 80/65 | 85±3.0 | 1.20±0.30 | ≤43.0 | 2.4±0.30 | 25 |

| 10kV WMPG 85/43* | 100/75 | 100±4.0 | 1.20±0.30 | ≤50.0 | 2.4±0.30 | 25 |

| 10kV WMPG 100/50 | 120/85 | 120±4.0 | 1.20±0.30 | ≤60.0 | 2.4±0.30 | 25 |

| 10kV WMPG 120/60 | 150/105 | 150±4.0 | 1.20±0.30 | ≤75.0 | 2.4±0.30 | 25 |

| 10kV WMPG 150/75 | 180/120 | 180±5.0 | 1.20±0.30 | ≤90.0 | 2.4±0.30 | 25 |

| 10kV WMPG 180/90 | 210/140 | 210±5.0 | 1.20±0.40 | ≤105 | 2.4±0.30 | 20 |

| 10kV WMPG 210/105* | 230/150 | 230±5.0 | 1.20±0.40 | ≤115 | 2.4±0.30 | 20 |

| 10kV WMPG 230/115* | 250/180 | 250±5.0 | 1.20±0.40 | ≤125 | 2.4±0.30 | 20 |

| 10kV WMPG 300/150* | 300/210 | 300±5.0 | 1.20±0.40 | ≤150 | 2.4±0.30 | 15 |

20kV Busbar Protection Heat Shrink Tubing

| Size | Applicable Busbar Width (square/round) | As Supplied (mm) | After Recovery (mm) | Packaging (m/reel) | ||

| Inside Diameter | Wall Thickness | Inside Diameter | Wall Thickness | |||

| 20kV WMPG 15/8 | 15/12 | 15±0.8 | 1.30±0.30 | ≤8.0 | 2.30±0.30 | 20 |

| 20kV WMPG 20/10 | 20/15 | 20±0.8 | 1.30±0.30 | ≤10.0 | 2.30±0.30 | 20 |

| 20kV WMPG 25/12 | 25/18 | 25±0.8 | 1.30±0.30 | ≤13.0 | 2.30±0.30 | 20 |

| 20kV WMPG 30/15 | 32/20 | 30±0.8 | 1.30±0.30 | ≤15.0 | 2.30±0.30 | 20 |

| 20kV WMPG 40/20 | 40/30 | 40±1.0 | 1.40±0.40 | ≤20.0 | 2.60±0.40 | 20 |

| 20kV WMPG 50/25 | 50/35 | 50±2.0 | 1.40±0.40 | ≤25.0 | 2.60±0.40 | 25 |

| 20kV WMPG 60/30 | 60/45 | 60±3.0 | 1.40±0.40 | ≤30.0 | 2.60±0.40 | 25 |

| 20kV WMPG 65/33* | 65/45 | 65±3.0 | 1.40±0.40 | ≤33.0 | 2.60±0.40 | 25 |

| 20kV WMPG 70/35 | 70/50 | 70±3.0 | 1.40±0.40 | ≤35.0 | 2.60±0.40 | 25 |

| 20kV WMPG 75/38 | 75/50 | 75±3.0 | 1.40±0.40 | ≤38.0 | 2.60±0.40 | 25 |

| 20kV WMPG 80/40 | 80/55 | 80±3.0 | 1.40±0.40 | ≤40.0 | 2.60±0.40 | 25 |

| 20kV WMPG 85/43* | 80/65 | 85±3.0 | 1.40±0.40 | ≤43.0 | 2.60±0.40 | 25 |

| 20kV WMPG 100/50 | 100/75 | 100±4.0 | 1.40±0.40 | ≤50.0 | 2.60±0.40 | 25 |

| 20kV WMPG 120/60 | 120/85 | 120±4.0 | 1.40±0.40 | ≤60.0 | 2.60±0.40 | 25 |

| 20kV WMPG 150/75 | 150/105 | 150±4.0 | 1.40±0.40 | ≤75.0 | 2.60±0.40 | 25 |

| 20kV WMPG 180/90 | 180/120 | 180±5.0 | 1.40±0.40 | ≤90.0 | 2.60±0.40 | 25 |

| 20kV WMPG 210/105* | 210/140 | 210±5.0 | 1.40±0.40 | ≤105 | 2.60±0.40 | 20 |

| 20kV WMPG 230/115* | 230/150 | 230±5.0 | 1.40±0.40 | ≤115 | 2.60±0.40 | 20 |

35kV Busbar Protection Heat Shrink Tubing

| Size | Applicable Busbar Width (square) | As Supplied (mm) | After Recovery (mm) | Packaging (m/reel) | ||

| Inside Diameter | Wall Thickness | Inside Diameter | Wall Thickness | |||

| 35kV WMPG 15/8 | 15/12 | 15±0.8 | 1.90±0.50 | ≤8.0 | 4.0±0.30 | 15 |

| 35kV WMPG 20/10 | 20/15 | 20±0.8 | 1.90±0.50 | ≤10.0 | 4.0±0.30 | 15 |

| 35kV WMPG 25/13 | 25/18 | 25±0.8 | 1.90±0.50 | ≤13.0 | 4.0±0.30 | 15 |

| 35kV WMPG 30/15 | 30 | 30±0.8 | 1.90±0.50 | ≤15.0 | 4.0±0.30 | 15 |

| 35kV WMPG 35/18 | 30/40 | 35±1.0 | 1.90±0.50 | ≤18.0 | 4.0±0.30 | 15 |

| 35kV WMPG 40/20 | 40 | 40±1.0 | 1.90±0.50 | ≤20.0 | 4.0±0.30 | 15 |

| 35kV WMPG 50/25 | 50 | 50±2.0 | 1.90±0.50 | ≤25.0 | 4.0±0.30 | 15 |

| 35kV WMPG 60/30 | 60 | 60±3.0 | 1.90±0.50 | ≤30.0 | 4.0±0.30 | 15 |

| 35kV WMPG 65/33* | 60/70 | 65±3.0 | 1.90±0.50 | ≤33.0 | 4.0±0.30 | 15 |

| 35kV WMPG 70/35 | 70 | 70±3.0 | 1.90±0.50 | ≤35.0 | 4.0±0.30 | 15 |

| 35kV WMPG 75/38* | 70/80 | 75±3.0 | 1.90±0.50 | ≤38.0 | 4.0±0.30 | 15 |

| 35kV WMPG 80/40 | 80/100 | 80±3.0 | 1.90±0.50 | ≤40.0 | 4.0±0.30 | 15 |

| 35kV WMPG 100/50 | 100/120 | 100±4.0 | 1.90±0.50 | ≤50.0 | 4.0±0.30 | 15 |

| 35kV WMPG 120/60 | 150 | 120±4.0 | 1.90±0.50 | ≤60.0 | 4.0±0.30 | 15 |

| 35kV WMPG 150/75 | 180 | 150±4.0 | 1.90±0.50 | ≤75.0 | 4.0±0.30 | 15 |

| 35kV WMPG 180/90* | MAX. | 180±5.0 | 1.90±0.50 | ≤90.0 | 4.0±0.30 | 15 |

| 35kV WMPG 210/105* | MAX. | 210±5.0 | 1.90±0.50 | ≤105 | 4.0±0.30 | 15 |

| 35kV WMPG 230/115* | MAX. | 230±5.0 | 1.90±0.50 | ≤115 | 4.0±0.30 | 15 |

| 35kV WMPG 250/125* | MAX. | 250±5.0 | 1.90±0.50 | ≤125 | 4.0±0.30 | 15 |

| 35kV WMPG 300/150* | MAX. | 300±5.0 | 1.90±0.50 | ≤150 | 4.0±0.30 | 15 |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos