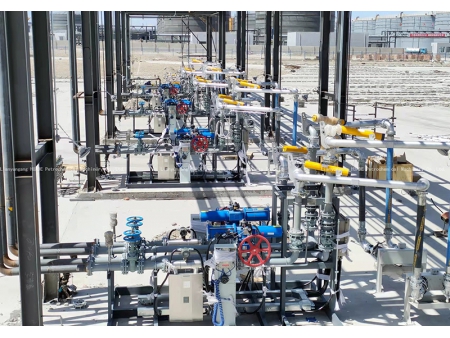

LNG Loading Skid

Request a Quote

LNG loading skid is a cryogenic loading and metering system that integrates the control system and cryogenic instruments into a movable skid frame according to the loading method. The instruments used in the loading skid are selected based on the properties of LNG.

Specifications

| Types | Liquid Pipeline | Gas Pipeline |

| Operating temperature | -196~50℃ | -196~50℃ |

| Design temperature | -196~60℃ | -196~60℃ |

| Operating pressure | 0.55MPa | 0.1~0.55MPa |

| Design pressure | 0.88MPa | 0.78MPa |

| Design flow rate | 60m³/h | 200m³/h |

| Medium | LNG | LNG |

| Nominal diameter | 2~3’’ | 2~3’’ |

- Plant instrument air: 0.5~0.7MPa (Plant gas supply of 0.6 MPa)

- Nitrogen purging: 0.4~0.8MPa (Plant gas supply of 0.7 MPa)

- Hazardous area: ZONE1

- Explosion proof: ExdII BT4 or higher

- Protection: IP65 or lower

Main functions

- Batch control: The LNG batch controller installed on the skid is activated upon receiving an order to begin loading. It follows a predetermined protocol that opens the valves and tracks the flow rate via a flowmeter. When the designated loading capacity is reached, the procedure is completed by closing the valves.

- Pre-cool tank: In order to load LNG safely, tank cars arriving at the loading station must be pre-cooled. This is done by spraying with low flow rate at the top, reducing the temperature in the tank through LNG gasification. Once the temperature in the tank has been lowered to around -100 degrees, full flow bottom loading can begin.

- Flow control: A flow control valve and mass flowmeter are installed on the loading skid to ensure the loading process is carried out smoothly and safely. The valve and meter work together to effectively regulate the flow rate.

- Nitrogen purging: Nitrogen purging is enabled by three nitrogen regulating valves fitted on the loading skid. These valves are used for nitrogen purging of the loading arm both before and after loading, as well as creating a nitrogen seal on the rotary joint, and for detection of any potential leaks.

- Temperature and pressure alarm: This control system is designed with pressure and temperature transmitters installed on the LNG and RG pipelines of the loading skid in order to monitor temperature and pressure during loading. If their values exceed the predetermined limit, an alarm will sound to alert the necessary personnel.

- Safe release of pressure: In an emergency, safety valves installed on the liquid, gas, and nitrogen pipeline of the loading skid act to regulate pressure in order to protect equipment and instruments within the skid. If the pressure exceeds the design limit, these safety valves will activate and ensure the safety of the system.

Features

- Every pipeline can be configured with automatic control valve to achieve automatic control of each loading operation by coupling with batch controller, (e.g. leakage detection → purging → pre-cooling → small flow transferring → mass transferring →purging) achieving one-key loading operation;

- The batch controller is equipped with IC card reader and keyboard, as well as display screen which indicates the status of valves and loading operation and guides operators to complete the operation step-by-step;

- All pipes, valves, instruments and electrical components are integrated in a base frame, and processes including assembling, welding, flaw detection, testing, and joint debugging of electrical components and control system are completed before leaving the plant; when used on site, operator only need to connect flanges and cables, greatly reducing the field installation and commissioning time;

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos