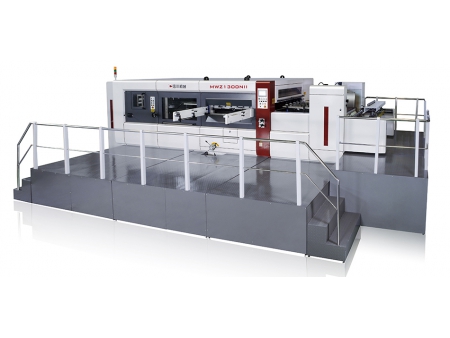

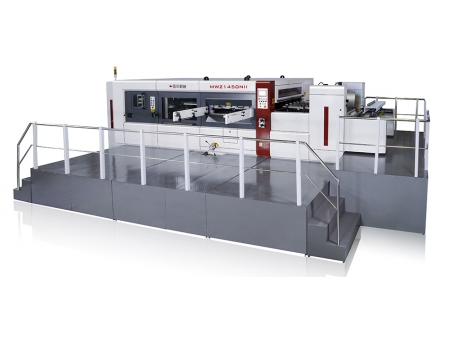

Automatic Flatbed Die Cutter, MWZ 1650G

Request a Quote

Technical Parameters

| Machine model | MWZ 1650G |

| Max. sheet size | 1650 x 1200mm |

| Min. sheet size | 650 x 500mm |

| Max. cutting size | 1630 x 1180mm |

| Cutting force | Up to 450tons |

| Max. mechanical speed | 5500 sheets per hour |

| Stock range | Corrugated sheet 0.8-8.5mm |

| Height of cutting rule | 23.8mm |

| Pressure adjustment | ±1.5mm |

| Cutting precision | ±0.5mm |

| Min. front waste | 10mm |

| Chase size | 1660x1210mm |

| Machine dimension | Length: 11200mm Width: 5560mm Height: 2600mm |

| Power consumption (without air pump) | 45kW |

| Machine weight | 38 Tons |

Machine Details

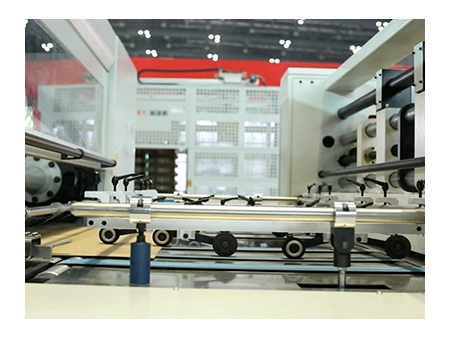

- Gear Driven Lead Edge Feeder

- High speed precise lead edge feeder ensures exceptional stability for sheet feeding.

- Back stopper with height adjustment function is suitable for feeding warped sheets.

- Side joggers keep pile of sheets in alignment to achieve accurate feeding.

- Adjustable support bar allows large format sheets feeding.

- Adjustable vacuum suction area supports full format sheets.

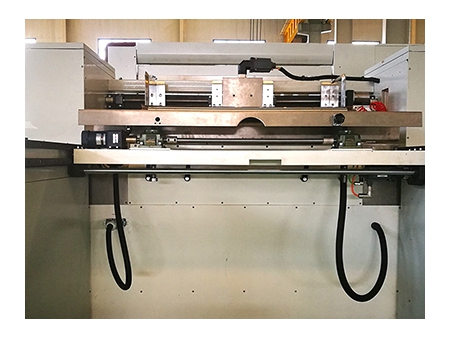

- Feeding Table

- Left and right-side push lays ensure accurate alignment and power registration.

- Sheets are accurately fed to die cutting unit with the aid of brush rollers and pressure rollers.

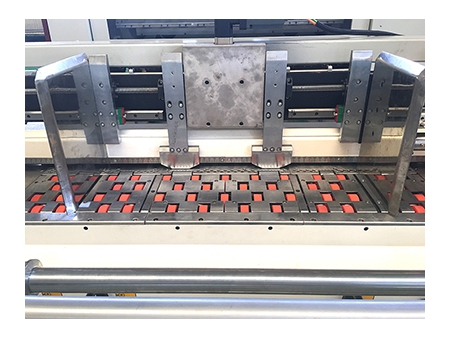

- Die Cutting Section

- Standard central positioning system paired with self-locking system enables fast job changeover and machine set-up.

- Overload protection is guaranteed thanks to the adoption of advanced gear box with torsion clutch.

- Automatic self-lubrication system is located independently and it is provided for minimal maintenance.

- Air floating device enables easy withdrawal of the cutting plate.

- 7 2mm cutting plate is made of 65Mn steel, suitable for recycling.

- Stripping Section

- Central positioning system makes it easier to set up the stripping die and enables fast job changeover.

- Heavy duty double action stripper efficiently removes waste, male and female stripping tools are provided to adapt to various stripping tasks.

- Front waste separator removes trim waste and transfers it to the machine drive side by conveyor belt.

- Delivery Section

- Automatic delivery system ensures non-stop production.

- Delivery action can be monitored through safety window to ensure safe operation, and side joggers are adjustable for neat stacking.

- Electrical Control Part

- All electrical components meet CE standard.

- Siemens PLC technology is adopted.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos