Cutting Software (Programming Software for Foam Cutting)

Our foam cutting software is functionally powerful, easy to use and easy to control. This makes programming and cutting more efficient. It enables complete cutting of graphic designs and provides functions to make the design process easier.

Here at Muye, we believe making things easy to use is incredibly important, thus our programming software is ready for convenient uses, no matter where you are in regards to production sites, design centers, or exhibition halls. You do not have to be a computer expert or be trained to be able to operate our foam cutting software, allowing you to focus on what’s important: doing the necessary jobs. As it is different from other software, ours has several features that are specifically used for foam cutting.

Graphic Design Features

1. Our foam cutting software is specifically developed for CNC foam cutting machines, allowing the user to draw precise patterns with only a few tools.

2. This foam cutting software features a great compatibility, allowing it to directly read graphic files drawn by other commonly used graphic design software.

3. The powerful automatic programming feature reduces programming time to as little as 2 or 3 minutes.

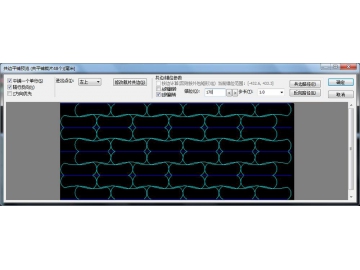

Process Control Features

1. This process control system has an independent CPU to control processing operations, allowing the drawing and processing to be carried out simultaneously. By doing so, our foam cutting software greatly improves production efficiency.

2. Modular automatic programming functions are added into the process control system. This enables fast programming of common regular shapes, like circles, rectangles, flakes and spirals. Just input parameters including the pattern diameter, foam size and clearance, and you will now have a complete foam cutting program in less than a minute.

3. Sample production and production in small quantities is available just by inputting this setting into the process control system. If you wish to make one or two sample foams, or foam in small quantities, you can easily start the process without redrawing or reprogramming, saving material and effort.

4. Our foam cutting software offers a more flexible method of processing. Users can freely perform mirroring, rotating, moving and inversing actions on graphics, allowing more shapes to be created.

5. We are the first company to apply a two-axis tool setting technology. Blade edge direction is memorized exactly to ensure the high precision of sponge products.

6. Reasonable angle embedding techniques are used to guarantee the high processing precision, even in extremely small or hard products.

7. The foam cutting software provides convenient data management. You can input the number of products, their costs, customer information and other information easily.

8. Intranet or Internet connection with other computers is available for remote sharing information sharing and remote assistance.

9. Reliable remote control enables easy operations, meaning employees do not need to move between the console and the foam production site. It also reduces waste material due to misuse of the cutting equipment.