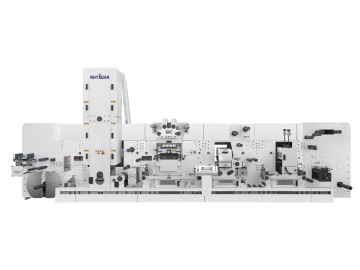

JK-5C1600-T Gravure and Emboss Combination Lines

Printing and embossing processes can be separate production lines or combined to give one production process.

- Machine width: 1600mm

- Print width: 1500mm

- Printing speed: 0-150m/min (depending on the material)

- Embossing speed: 0-35m/min

- Number of colors in registered printing: 5 colors

- Registered printing precision: ±0.2mm

- Registered embossing precision: ±1mm

- Plate cylinder diameter: ⌀ 150~⌀ 380mm

- Cylinder mounting: shaftless cylinder chucking

Designed with Electronic Line Shaft Technology (ELS), printing and embossing processes can be separate production lines or combined to give one production process. This provides great benefit for the users due to its multiple functions, making it ideal for use in the production of wallpapers, floor covering, etc.

Two operation modes available: printing with register embossing mode and printing mode

1. Printing with register embossing mode: With a production speed up to 35m/min, the gravure and emboss combination line is mainly used for intaglio printing and register embossing on PVC material in a synchronous manner. At first, various patterns are printed on the PVC material; then laminate with clear PVC material; finally, register embossing is performed. Matching embossing with color printing perfectly realizes quality visual appearance.

2. Printing mode: With a production speed up to 150m/min, the production efficiency is as high as that of one common type gravure printing press with electronic line shaft.

- Web tension range: 5-50kg (at full load)

- Tension control precision: ±0.5kg

- Max. force of the impression cylinder: 1500kg

- Heating method: available with electric heating or thermal oil heating

- Applicable ink: oil-based ink, water-based ink

- Main processed materials: plastic films including PVC, PE, OPP, BOPP, PET

Main Configurations

- 1 winding and unwinding unit for each station (two stations in total)

- 1 preheating and flattening unit

- 5 print units

- 2 traction units

- 4 sets of laminating and preheating unit

- 1 embossing unit

- 1 cooling unit

Custom Options

- In addition to standard configurations, we can also configure the equipment upon request to meet unique processing needs.

- The gravure and emboss combination line can be individually configured to process the materials with width range of 1-2.3m.

- We offer 1-8 color rotogravure printing machines to accommodate printing needs.