Non-Fried Instant Noodle Production Line

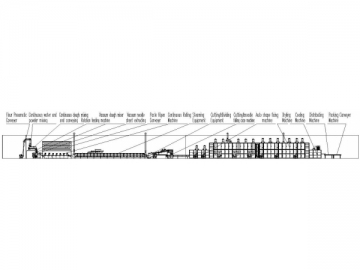

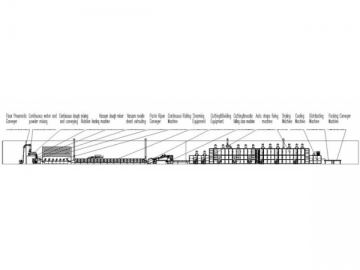

- Continuous Water and Flour Mixer

- Continuous Vacuum Dough Mixer

- Continuous Vacuum Noodle

Sheet Extruder - Paste Ripening Conveyer

- Continuous Rolling Machine

- Multilayer Steamer

- Seasoning & Straightening

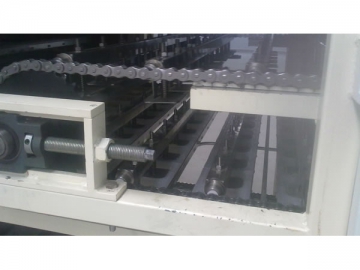

Machine - Cutting & Distributing Machine

- Automatic Forming Machine

- Drying Machine

- Round Case Packaging Machine

- Square Case Packaging Machine

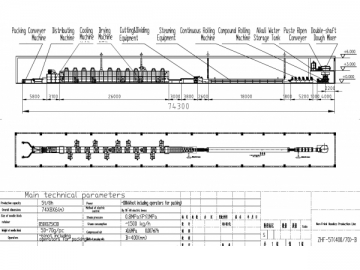

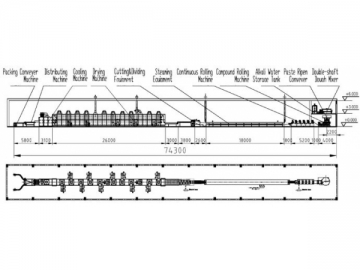

ZHF-(2~20)W-S Non-Fried Instant Noodle Production Line Layout

ZHF-5T(40070)-B Non-Fried Instant Noodle Production Line Layout 20130821-Model

Our non-fried instant noodle production line comprises continuous water and flour mixer, continuous vacuum dough mixer, continuous vacuum noodle sheet extruder, paste ripening conveyer, continuous rolling machine, multilayer steamer, seasoning & straightening machine, cutting & distributing machine, automatic forming machine, drying machine, round case and square case packing machine. These machines can be used in different combinations to suit the actual production needs.

Generally, non-fried instant noodle is the noodle belt or sheet dried and dehydrated by 80-100℃ hot air, resulting in elimination of high-temperature oxidized cooking oil. Compared to fried instant noodle, this kind of snack food has lower fat and heat, and is more preferred for boiling rather than soaking in hot water. We regard all dried instant noodles as non-fried noodles including fined dried noodle, ramen, boiled noodle and egg noodle. Healthy concept is responsible for its promising market.

Advantage

1. Large Output Volume

Tremendous production rate of this food equipment is ensured at low cost. 3,000 kg instant noodles can be produced every hour.

2. High Automation

Our non-fried instant noodle production line is fitted with human machine interface, PLC control system and variable frequency speed control system, thus offering easy and efficient operation.

3. Exceptional Durability

Modern appearance comes with energy-saving enclosed cooling device and high hardness alloy iron roll. The entire dried noodle production system meets hygiene requirements.

4. Prominent Versatility

Instant noodle production line is regarded as the non-standard wheaten food manufacture equipment. Our custom noodle processing machine is allowed for various configurations to cater to diverse applications. Specific solution depends on output volume, plant size, automation degree and quality requirement. For example, both rolling machine and steamer can be modified to fit different needs.

A. Rolling Machine

The rolling machine in this instant noodle production line can be driven by single or multiple electric motors. The first model utilizes one electric motor to power all roller groups. Speed of each group is synchronously controlled when rolling machine is adjusting noodle sheet thickness. As for the second model, each roller group is fitted with one motor. The rolling speed is PLC controlled with the aid of photoelectric switch on each group.

B. Steamer

Steamer can be different in single layer and multiple layers. Normally, multi-layer model has 3 layers. Obviously, comparing to single layer model, multi-layer steamer saves 3 times floor space for the entire non-fried instant noodle production line.

Specification

| Model | Capacity (×10,000 pcs/8 hours) | Dimensions (m) | Power (kW) | Roller size (mm) | Staffing | Steam consumption (kg/h) |

| 2-3 | 52 × 6 × 6 | 50 | 240 | 4 | 800-1000 | |

| 4-5 | 60 × 6 × 6 | 56 | 360 | 5 | 1000-1500 | |

| 6-8 | 68 × 6 × 6 | 72 | 480 | 6 | 1500-1800 | |

| 9-12 | 76 × 6 × 6 | 102 | 600 | 7 | 1800-2200 | |

| 13-16 | 84 × 8 × 6 | 120 | 600 | 8 | 2200-2500 | |

| 17-20 | 96 × 8 × 6 | 150 | 720 | 9-10 | 2500-3000 |

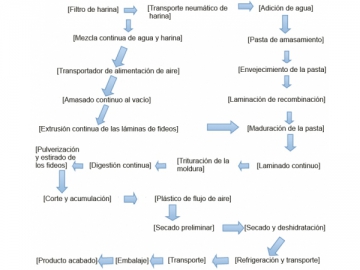

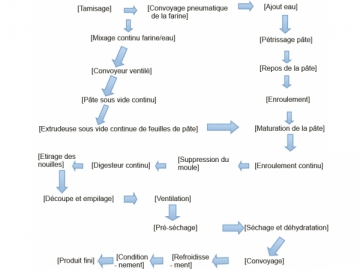

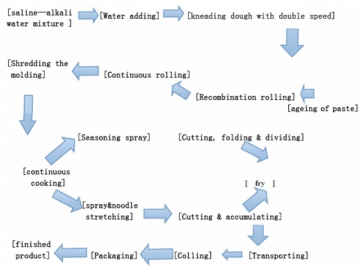

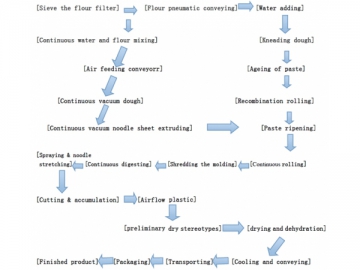

Production Process

Production Parameters

1. Water content in kneading dough: 28%-50%

2. Dough kneading time: 10-15 minutes

3. Kneading vacuum degree: 0.07-0.09MPa

4. Paste ripening time: up to 30 minutes

5. Steaming time: ≥180s

6. Noodle level: α:>95%

7. Drying time: 45-90 minutes

8. Drying temperature: 80℃-110℃

9. Air cooling time: ≥3 minutes