Tunnel Metal Detector

Metal Detection Equipment

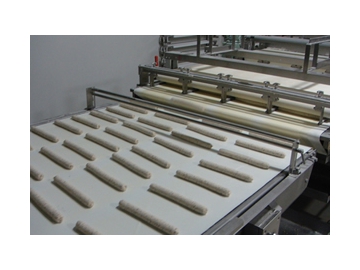

Metal detection system for detecting metallic impurities in non-metallic materials transported on conveyors

Tunnel metal detector is designed based on the principle of electromagnetic induction to identify various metal foreign objects such as iron, stainless steel, copper, aluminum, etc. mixed into products. When the system detects metal foreign objects, it sends a signal to the equipment's control system to alert and prompt the removal of non-conforming products or automatically separate the product through a separation device. The purpose of the metal detection system is to ensure food and drug safety, avoid customer complaints, product recalls leading to direct economic losses, and intangible brand image losses, as well as to protect downstream production equipment such as cutting tools and molds from damage by metal foreign objects. Metal detection systems are essential equipment for annual audits of food and drug manufacturers.

SINBON has been engaged in the research, development, and application of metal detection systems for nearly 20 years, with rich experience in configuring suitable metal detection systems for you.

- Tunnel Metal Detector with Control System

- Pharma Metal Detector MD-25 Series

- Industrial Conveyor Metal Detector SBI Series

- Free-Fall Metal Detector FMD Series

- Pipeline Metal Detector LMD Series

| Detection Principle | Balanced coil (based on the principle of electromagnetic induction) |

| Tunnel Size | Length: 80-1600mm (customizable) Width: 80-600mm (customizable) |

| Optimal Sensitivity | Fe: Ø0.25mm; Non-Fe: Ø0.4mm; SUS316: Ø0.4mm; |

| Alarm | Acoustic alarm |

| Power Source | AC220V;50HZ;1P |

| Operation System | SINBON multilingual control system |

- Tunnel metal detector can accurately detect magnetic and non-magnetic metal foreign objects mixed into products.

- Metal detection system prevents downstream production equipment from damage or downtime for maintenance.

- Avoid losses caused by customer complaints and product recalls.

- Low equipment maintenance costs, long service life, and quick recovery of equipment costs.

- The metal detection equipment has a self-learning function, and the product setting operation is simple (Auto Product Learn, the machine automatically learns and stores corresponding data for products).

- Up to 32 product preset storage functions allows for quick product switching.

- Multi-language operating system allows for easy operation by local personnel.

- Password protection function prevents unauthorized personnel from changing settings.

- Counting and statistical functions, report printer (optional).

- IP65 protection level, strong and durable.

- Non-standard metal detectors with different channel sizes are customizable.

- Conveyor

- Touch Screen

- Rejection Mechanism (air-blowing rejection, push-plate rejection, inclined conveyor belt rejection, powered roller conveyor rejection)