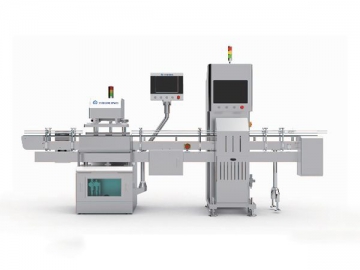

Induction Sealing Machine

Request a Quote

for sealing bottle opening with aluminum foil

Induction sealing machine utilizes the eddy current magnetic field generated when electromagnetic waves come into contact with metal substances, causing the metal to instantaneously heat up and complete the fusion of the aluminum foil and bottle opening, achieving the purpose of automatic sealing. Electromagnetic induction sealing technology is recognized internationally as an advanced sealing packaging method in contemporary times and is increasingly widely used in high-quality airtight sealing of pharmaceuticals, food, cosmetics, pesticides, chemical products, and other bottled products.

Snap Capping Machines We Offer

- Water-Cooled Electromagnetic Induction Cap Sealer DG-5000A

- Air-Cooled Electromagnetic Induction Cap Sealer DG-3000E/F

- Handheld Electromagnetic Induction Sealer F200

Applications

- Plastic bottles, glass bottles

Specifications

| Cooling Method | High speed water cooling / air cooling |

| Sealing Diameter | Ø15-55 mm/Ø30 -75 mm/ Ø60 -140 mm |

| Output Power | 1500w/3000W/5000W |

| Sealing Speed | 50-750BPM |

| Height of Induction Head from Ground | 760-1180 mm |

| Power Source | AC220V; 50HZ; 1Phase; 20A |

| Structure | 304 stainless steel, split design, easy to maintain |

Features

- Anti-corrosion host design: outer shell of the host is made of 304 stainless steel, and the device circuit and cooling air duct are completely isolated, effectively preventing corrosion of the main circuit components by corrosive gases.

- Heating sensor: temperature control protection function. When the temperature is too high, the machine immediately stops outputting and emits an alarm sound and light.

- Stable and reliable performance:The sealing machine has special design and perfect self-diagnosis and protection system to protect itself in various extreme conditions. The sealing machine can intelligently sound and light alarm externally and accurately determine the fault location, facilitating user inspection and troubleshooting.

- Equipped with an intelligent water tank: The water tank provides circulating cooling water for the heating sensor, allowing the host and sensor to work stably and reliably for a long time, while significantly increasing the output power of the induction head and extending the life of the sensor.

- Interchangeable with other devices of the same model: this effectively reduces operating costs and makes the maintenance more convenient.

Optional

- Aluminum foil detection device (with missing aluminum foil alarm and rejection function)

- Conveyor

FAQ

Our induction sealing machine is suitable for sealing plastic and glass bottles with aluminum foil. In order to accurately determine its suitability, buyers need to provide necessary information such as photos of the bottle and cap, bottle opening diameter, bottle and cap material, etc., and contact our sales team for assistance in confirming the appropriate machine configuration.

While local service points are limited, buyers may seek assistance from local dealers, if available. Prior to leaving the factory, the machine undergoes complete assembly and testing and is shipped fully assembled, requiring no special installation or debugging. Simply power on the machine for use and reference the manual or instructional videos for parameter settings. In the event of any issues, contact the seller for online guidance and support.

Our induction sealing machine comes with a 12-month warranty, excluding consumable parts. Within the warranty period, replacement parts are provided at no additional cost (excluding shipping expenses), while reasonable fees apply for parts outside the warranty coverage. Lifetime free remote technical support is also offered for the equipment.

Contact us promptly for assistance in resolving the issue. We can conduct real-time remote fault diagnosis and promptly ship replacement parts if needed.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos