HDD Drill Pipe (Integral Type)

Material use OCTG, reliable performance;

Using a unique tool joints twice thicker molding technology;

Transition band is smooth , which can reduce resistance through the mud;

Thread of joints liquid nitrogen treatment, surface hardness higher, thereby pipe life is longer.

Specification of Forged Drill Pipe for Vermeer HDD Machine

| Model of Rig | Connection | Dimension of Drilling Pipe | Tempering and Quenching | Min Bending Radius | Max Torque | ||||

| OD of Tube | Wall Thickness | OD of Joints /upset | Working Length | Weight | |||||

| (mm) | (mm) | (mm) | (mm) | ( kg) | Grade | (m) | Nm | ||

| D7×11, D9×13 | Firestick 1 | 42 | 6.5 | 48 | 1829 | 12 | S135 | 29 | 2000 |

| D10×14, D10×15 | Firestick 1 | 42 | 6.5 | 48 | 3048 | 20 | S135 | 29 | 2000 |

| D16×20, D18×22 | Firestick 1 | 48 | 6.5 | 54 | 3048 | 23.5 | S135 | 30 | 3000 |

| D24×26 | Firestick 1 | 54 | 7 | 57 | 3048 | 25 | S135 | 31 | 4000 |

| D24×40 | Firestick 1 | 60.3 | 7.5 | 66.7 | 3048 | 35 | S135 | 33 | 6300 |

| D40×40 | Firestick 1 | 60.3 | 7.5 | 66.7 | 4572 | 50 | S135 | 33 | 6300 |

| D33×44, D36×50 | Firestick 1 or 2 | 60.3 | 7.5 | 70 | 3048 | 36 | S135 | 33 | 6772 |

| D33×44, D36×50 | Firestick 1 or 2 | 60.3 | 7.5 | 70 | 4572 | 51 | S135 | 33 | 6772 |

| D36×50 | Firestick 1 | 60.3 | 7.5 | 70 | 3048 | 36 | S135 | 33 | 6772 |

| D36×50 | Firestick 1 | 60.3 | 7.5 | 70 | 4572 | 51 | S135 | 33 | 6772 |

| D36×50 | Firestick 1 | 66.7 | 8 | 78 | 3048 | 40 | S135 | 40 | 9000 |

| D36×50 | Firestick 1 | 66.7 | 8 | 78 | 4572 | 55 | S135 | 40 | 9000 |

| D50×100,Uni60×70 | Firestick 1 | 73 | 10 | 83 | 3048 | 55 | S135 | 51 | 16000 |

| D50×100 | Firestick 1 | 73 | 10 | 83 | 4572 | 78 | S135 | 51 | 16000 |

| D50×100, D80×100 | Firestick 1 | 89 | 10 | 92 | 4572 | 96 | S135 | 72 | 18000 |

| D100×120 | Firestick 2 | 89 | 10 | 104 | 6096 | 130 | S135 | 72 | 24000 |

| D100×120 | Firestick 1 | 89 | 11.5 | 111.5 | 6096 | 150 | S135 | 80 | 27000 |

Specification of Forged Drill Pipe for Ditch Witch HDD Machine

| Model of Rig | Connection | Dimension of Drilling Pipe | Tempering and Quenching | Min Bending Radius | Max Torque | ||||

| OD of Tube | Wall Thickness | OD of Joints /upset | Working Length | Weight | |||||

| (mm) | (mm) | (mm) | (m) | ( kg) | Grade | (m) | Nm | ||

| JT820/920 | DW | 42 | 6.5 | 50.8 | 2 | 13 | S135 | 26 | 2000 |

| JT920L | DW | 42 | 6.5 | 50.8 | 3 | 21 | S135 | 26 | 2000 |

| JT1720 /1720M1 | DW | 52 | 6.5 | 63 | 3 | 25 | S135 | 30 | 3200 |

| JT2020M1 | DW | 60 | 7.5 | 66.7 | 3 | 35 | S135 | 33 | 6300 |

| JT2720 | DW | 60 | 7.5 | 70 | 3 | 36 | S135 | 33 | 6772 |

| JT2720M1/3020M1 | DW | 68 | 8 | 76 | 3 | 40 | S135 | 33 | 7000 |

| JT4020 | DW | 73 | 10 | 82.5 | 4.5 | 51 | S135 | 51 | 16000 |

| JT4020M1 | DW | 83 | 9 | 89 | 4.5 | 84 | S135 | 65 | 18000 |

| JT7020 /8020 | DW | 89 | 10 | 101.6 | 4.5 | 100 | S135 | 72 | 24000 |

Specification of Forged Drill Pipe for Case HDD Machine

| Model of Rig | Connection | Dimension of Drilling Pipe | Tempering and Quenching | Min Bending Radius | Max Torque | ||||

| OD of Tube | Wall Thickness | OD of Joints | Working Length | Weight | |||||

| (mm) | (mm) | (mm) | (m) | ( kg) | Grade | (m) | Nm | ||

| Case 6030 | Case | 60.3 | 7.5 | 66.7 | 3.048 | 35 | S135 | 33 | 6300 |

| Size | Dimension of Drlling Pipe | Small clamp space of pin/box joints | Thread | Steel Grade | Min bending Radius | The length of drill bent at 90° | Max bending angle | Max percentage of drill pipe | Torque | ||||

| OD of Tube | Wall Thickness | Workinglength | Weight | OD ofJoints | |||||||||

| (mm) | (mm) | (m) | (kg) | (mm) | (mm) | (m) | (m) | (%) | (KN.m) | ||||

| 50(2″) | 50 | 6.5 | 2 | 20 | 57 | Pin:110 | DH50 | G | 38 | 60 | 3.0″4.8″ | 5.2 | 2.9 |

| 2.5 | 25 | Box:175 | S | 30 | 47.1 | 8.3 | 3 | ||||||

| 60.3(2 3/8″) | 60.3 | 7.5 | 2 | 25.3 | 67 | Pin:130 | DH60 | G | 42 | 66 | 2.7″5.2″ | 4.8 | 6 |

| 3 | 37 | Box:180 | S | 33 | 51.8 | 9.1 | 6.3 | ||||||

| 73(2 7/8″) | 73 | 8 | 3 | 45 | 80 | Pin:120 | DH23 | G | 58 | 91.1 | 3.0″3.8″ | 5.2 | 12 |

| 4 | 58 | Box:180 | S | 45 | 70.7 | 5 | 13 | ||||||

| 73(2 7/8″) | 73 | 10 | 3 | 58 | 87 | Pin:120 | DH26 | G | 67 | 105 | 2.6″4.5″ | 4.5 | 14.5 |

| 4 | 78 | Box:180 | S | 51 | 80 | 7.8 | 16 | ||||||

| 83(3 1/4″) | 83 | 9 | 3 | 59 | 92 | Pin:130 | WM80 | G | 73 | 114.7 | 2.4″4.0″ | 4.1 | 16.818 |

| 4.5 | 84 | Box:190 | S | 65 | 102.1 | 6.9 | |||||||

| 89 (3 1/2″) | 88.9 | 10 | 4.5 | 102 | 104 | Pin:150 | DH31 | G | 80 | 125.7 | 3.2″4.8″ | 5.6 | 22.324 |

| 6 | 130 | Box:230 | S | 72 | 113 | 8.3 | |||||||

| Yield stength | Tensile stength | Elongation rate | Impact work | |||||

| Steel | Min | Max | Min | Min | 10×10 | |||

| Grade | Psi | Mpa | Psi | Mpa | Psi | Mpa | % | (-20℃) |

| iG105 | 105,000 | 724 | 135,000 | 931 | 115,000 | 793 | 15 | ≥68 |

| S135 | 135,000 | 931 | 165,000 | 1138 | 145,000 | 1000 | 13 | ≥54 |

HDD Drill Pipe

Material use OCTG, Pipe end upsetting meet API standard; Thicker tube body quenching and heat treatment, Steel Grade up to G105 or S135;

Welding area using thermo mechanical treatment, welding performance conform to API SPEC 7 Standard.

| Tube | Joint | ||||||||||||

| Size | Weight | Steel Grade | Upsetting | O.D | Wall thickness of pipe | Thread | OD of joints | ID of joints | Diameter of angling | Big clamp space of pin joints | Big clamp space of box joints | OD of welding | Bearing torque comparison |

| (mm) | d(mm) | d(mm) | LPB(mm) | LPB(mm) | joint DTE/DPE(mm) | ||||||||

| 3 1/2 | 13.3 | R | EU | 88.9 | 9.35(11.4) | NC31 | 104.8 | 50.8 | 100.41 | 177.8 | 228.6 | 80.96 | 0.98 |

| G | 104.8 | 50.8 | 100.41 | 177.8 | 228.6 | 80.96 | 0.87 | ||||||

| S | 104.8 | 41.28 | 100.41 | 177.8 | 228.6 | 80.96 | 0.86 | ||||||

| 4 | 14 | R | EU | 101.6 | 8.38(9.19) | NC38 | 127 | 65.09 | 116.28 | 203.2 | 266.7 | 98.43 | 0.97 |

| G | 127 | 61.91 | 116.28 | 203.2 | 266.7 | 98.43 | 0.83 | ||||||

| S | 127 | 53.98 | 116.28 | 203.2 | 266.7 | 98.43 | 0.9 | ||||||

| 4 1/2 | 16.6 | E | IEU | 114.3 | 8.56 | NC46 | 158.8 | 82.55 | 145.26 | 177.8 | 254 | 119.06 | 1.09 |

| X | 158.8 | 72.6 | 145.26 | 177.8 | 254 | 119.06 | 1.01 | ||||||

| G | 158.8 | 76.2 | 145.26 | 177.8 | 254 | 119.06 | 0.91 | ||||||

| S | 158.8 | 69.85 | 145.26 | 177.8 | 254 | 119.06 | 0.81 | ||||||

| 20 | E | 10.92 | 158.75 | 76.2 | 145.3 | 177.8 | 254 | 119.07 | 1.07 | ||||

| X | 158.75 | 69.85 | 145.3 | 177.8 | 254 | 119.07 | 0.96 | ||||||

| G | 158.75 | 63.5 | 145.3 | 177.8 | 254 | 119.07 | 0.93 | ||||||

| S | 158.75 | 57.15 | 145.3 | 177.8 | 254 | 119.07 | 0.81 | ||||||

| Tube | Joint | ||||||||||||

| Size | Weight | Steel Grade | Upsetting | O.D | Wall thickness | Thread | OD of joint | ID of joint | Dimeter of angling | Big clamp space of the pin joint | Big clamp space of the box joint | OD of welding | Bearing torque comparison |

| (mm) | (mm) | d(mm) | d(mm) | DF(MM) | LPB(mm) | LPB(mm) | joint DTE/DPE(mm) | ||||||

| 4 1/2 | 16.6 | E | EU | 114.3 | 8.56 | NC50 | 168.28 | 95.25 | 154 | 177.8 | 254 | 127 | 1.23 |

| X | 168.28 | 95.25 | 154 | 177.8 | 254 | 127 | 0.97 | ||||||

| G | 168.28 | 95.25 | 154 | 177.8 | 254 | 127 | 0.88 | ||||||

| S | 168.28 | 88.9 | 154 | 177.8 | 254 | 127 | 0.81 | ||||||

| 20 | E | 10.92 | 168.28 | 92.08 | 154 | 177.8 | 254 | 127 | 1.07 | ||||

| X | 168.28 | 88.9 | 154 | 177.8 | 254 | 127 | 0.96 | ||||||

| G | 168.28 | 88.9 | 154 | 177.8 | 254 | 127 | 0.96 | ||||||

| S | 168.28 | 76.2 | 154 | 177.8 | 254 | 127 | 0.81 | ||||||

| 5 | 19.5 | E | IEU | 127 | 9.19 | 168.28 | 95.25 | 154 | 177.8 | 254 | 130.18 | 1.23 | |

| X | 168.28 | 88.9 | 154 | 177.8 | 254 | 130.18 | 0.97 | ||||||

| G | 168.28 | 82.5 | 154 | 177.8 | 254 | 130.18 | 0.88 | ||||||

| S | 168.28 | 69.85 | 154 | 177.8 | 254 | 130.18 | 0.81 | ||||||

| 25.6 | E | 12.7 | 168.28 | 88.9 | 154 | 177.8 | 254 | 130.18 | 1.02 | ||||

| X | 168.28 | 76.2 | 154 | 177.8 | 254 | 130.18 | 0.96 | ||||||

| G | 168.28 | 69.85 | 154 | 177.8 | 254 | 130.18 | 0.86 | ||||||

| S | 168.28 | 69.85 | 154 | 177.8 | 254 | 130.18 | 0.87 | ||||||

| 19.5 | E | 9.19 | 5 1/2FH | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 130.18 | 1.53 | |||

| X | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 130.18 | 1.21 | ||||||

| G | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 130.18 | 1.09 | ||||||

| S | 184.15 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 0.98 | ||||||

| 25.6 | E | IEU | 12.7 | 177.8 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 1.21 | |||

| X | 177.8 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 0.95 | ||||||

| G | 184.15 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 0.99 | ||||||

| S | 184.15 | 82.55 | 170.7 | 203.2 | 254 | 130.18 | 0.83 | ||||||

| 5 1/2 | 21.9 | E | 139.7 | 9.17 | 177.8 | 101.6 | 170.7 | 203.2 | 254 | 144.46 | 1.11 | ||

| X | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 144.46 | 0.98 | ||||||

| G | 184.15 | 88.9 | 170.7 | 203.2 | 254 | 144.46 | 1.02 | ||||||

| S | 190.5 | 76.2 | 180.2 | 203.2 | 254 | 144.46 | 0.96 | ||||||

| 24.7 | E | 10.54 | 177.8 | 101.6 | 170.7 | 203.2 | 254 | 144.46 | 0.99 | ||||

| X | 184.15 | 88.9 | 170.7 | 203.2 | 254 | 144.46 | 1.01 | ||||||

| G | 184.15 | 88.9 | 170.7 | 203.2 | 254 | 144.46 | 0.92 | ||||||

| S | 190.5 | 76.2 | 180.2 | 203.2 | 254 | 144.46 | 0.86 | ||||||

| 6 5/8 | 25.2 | E | 168.3 | 8.38 | 6 5/8 FH | 203.2 | 127 | 195.7 | 203.2 | 279.4 | 176.21 | 1.04 | |

| X | 203.2 | 127 | 195.7 | 203.2 | 279.4 | 176.21 | 0.82 | ||||||

| G | 209.55 | 120.65 | 195.7 | 203.2 | 279.4 | 176.21 | 0.87 | ||||||

| S | 215.9 | 107.95 | 195.7 | 203.2 | 279.4 | 176.21 | 0.86 | ||||||

| 27.7 | E | 9.19 | 203.2 | 127 | 195.7 | 203.2 | 279.4 | 176.21 | 0.96 | ||||

| X | 209.55 | 120.65 | 195.7 | 203.2 | 279.4 | 176.21 | 0.89 | ||||||

| G | 209.55 | 120.65 | 195.7 | 203.2 | 279.4 | 176.21 | 0.81 | ||||||

| S | 215.9 | 107.95 | 195.7 | 203.2 | 279.4 | 176.21 | 0.8 | ||||||

Winged Reamer (Φ200—Φ1800)

Suitable for hard soil strata and strong-mantle rock formations.

Connection with drill rod: direct connection with drill rod; octagonal connection

Connection with pipeline: with and without swivel

Sub actuator

(15T,20T,40T,60T,80T,100T,200T,300T,400T,500T,600T,700T,800T)

By using the latest optimization design, greatly improving the

service life of the actuator, and minimizing the risk of the construction.

Slider & Shackle

Slider using alloy steel and heat treatment,

the shackle using bow cross pin with nut for high safety.

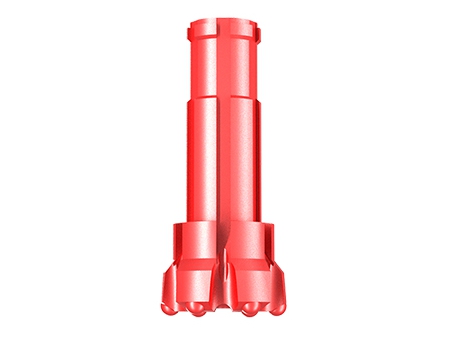

Oriented Drill

Oriented drill (2 3/8 ~ 6 5/8FH)

Connection: Direct connection with drill pipe, octagonal connection, side-opening

Signal bar handling mode: rear-mounted, side-mounted

Cutting Blade

The user can choose different cutting blades according to different

geological conditions to improve cutting efficiency of the reamer.

Drill Collar

Using heat-treated high quality alloy

steel, high strength and durability.

Reamer

Ripper Reamer (Φ200—Φ1800)

Suitable for soft soil strata.

Connection with drill rod : direct connection

with drill rod; octagonal connection;

Connection with pipeline: with and without swivel.