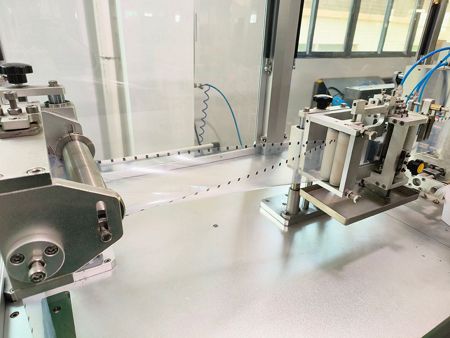

Double Sided Blister Packaging Machine , DC-860

Request a Quote

Liquid & paste filling and sealing machine for dual-sided blister packs

The DC-860 double-sided blister packaging machine is the ideal solution for packing liquids and viscous products. Constructed with thoughtful design and safety considerations, this blister packaging machine is capable of using a plastic film roll to reliably package your materials. Not only does it come with a simpler structure, but it also minimizes the cost of production.

This packaging machine is optimal for packaging, providing a range of possibilities with various materials such as PVC (PE), PET (PE), PVDC and more. Utilization rate of packaging materials is high, with most reaching more than 95% and some even up to 99%.

Specifications

| Machine dimensions (L×W×H) | 2100×1150×1400mm |

| Machine weight | 1400Kg |

| Power supply | 3 phase, 380V, 50Hz |

| Packaging materials | PVC/PE, PET/PE, PVDC, and other laminated films |

| Package size | (0.3-0.4)*240max.(mm) (or depending on mold size) |

| Max. diameter of film roll | Ø 400mm |

| Inner diameter of film roll core | Ø 76mm |

| Blisters per pack | 2-5 blisters/pack (depending on filling dosage) |

| Filling efficiency | 10-20 cycles/min |

| Dosage | 1-20ml |

| Filling accuracy | ≤2%, in compliance with national standards. |

| Forming depth of double-sided blister | 10-20mm |

| Forming depth of single-sided blister | 2-10mm |

- Modular design offers simple machine structure, allows for a swift design cycle, and thus quicker product updates.

- Sturdy architecture, dependable quality, unfailing performance and extended service life.

Guide buffer wheel

Guide buffer wheel PLC operation interface and temperature control

PLC operation interface and temperature control Sealing device

Sealing device Cursor positioning unit

Cursor positioning unit Film closing device

Film closing device Film roll

Film roll Mould forming and feeding device

Mould forming and feeding device Export of waste film and finished product

Export of waste film and finished product

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos