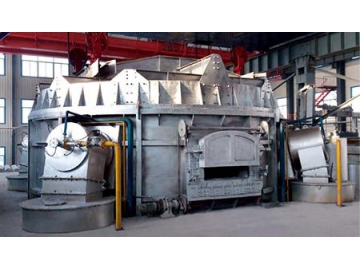

Suspension Melting Furnace

The suspension melting furnace is renowned for bringing no pollution. Cold crucible of this metal melting furnace comes in 150mm inner diameter. Generally, our induction melting furnace is capable of melting 10kg steel or 5kg titanium each time.

Advantage

1. All suspension

Melting process is conducted in suspension state, resulting in no unmelted or semi-melted materials being adhered to crucible side or bottom.

2. No impurities

Content of impurities is no more than original content.

3. Balanced composition

Output product is endowed with uniformed composition. The deviation between finished production composition and ingredient composition, as well as composition in various parts of finished product is no more than 1%.

4. Low energy consumption

Although our suspension melting furnace is fitted with larger power than normal induction melting furnace, one melting cycle can be done within only 5 minutes.

5. Long service life

The crucible in suspension melting equipment is born with time-verified durability. Based on over decades of applications, there have never been situations that partial crucible melting or copper flowing into liquid furnace charge.

Technical data

Inner diameter of cold crucible: 150mm

High-frequency power supply: 250kW

Max. melting temperature: 1750°C

Vacuum system: Mechanical pump-Roots pump-Diffusion pump

Vacuum degree: Max. vacuum degree: 8×10-4 Pa, vacuum degree≥5×10-3 Pa (0.5 hour after diffusion pump starts working), leak rate≤0.5Pa/h

Furnace body: vertical, dual-layer water cooled, stainless steel inner plate, inner diameter: 1000mm

Structure

1. Main valves in vacuum system of our suspension melting furnace are responsible for pneumatic-electromagnetic operation.

2. Programmed type digital composite vacuum meter is available.

3. High-purity argon is applicable. The argon charging is commenced at 0.2 seconds delay after high vacuum valve is closed. The charging process is finished within 30 seconds with adjustable pressure.

4. There is feeding chamber, allowing for batch feeding.

5. Pneumatic tilting and casting system is available. Moulds can be incorporated with heating and cooling component.

6. Casted blank can be re-melted without requiring opening furnace.

7. This suspension melting furnace is equipped with circular water cooling system, featuring protection on over temperature and water shortage.

8. Operation system falls into manual control, automatic control and programmable control for selection.

Options

1. Furnace body structure and size can be adjusted.

2. Furnace body, vacuum tube and valves can be all made from stainless steel.

3. With the aid of infrared temperature meter, melting process is allowed for closed-loop control.

4. Casting unit is compatible with pressure casting and centrifugal casting unit.

5. Multiple furnace structure is available. On the condition of remaining argon atmosphere, melting and casting in the first furnace is followed by the same production process in the second and third furnace. The repeat times are accordance with negotiation between customer and supplier.

6. Uphill casting and continuous casting functions are also available.

- Automatic Pusher Sintering Furnace

- Spark Plasma Sintering Furnace (SPS)

- High Temperature Graphite Furnace

Related Names

Suspension Furnace | Metal Melting Furnace | Smelting Furnace