Dense Phase Pneumatic Conveying System

DensePhase Pneumatic Conveying System

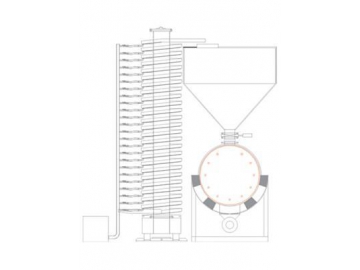

CONLY dense phase pneumatic conveying system utilizescompressed air supply from air compressor to transport powder or particlematerials inside piping system. Our pipe conveyingequipment has been successfully applied to all sizes of enterprises inindustries of plastic, building materials and chemical, etc.

Advantages

1. This high pressure pneumatic conveying machine features exceptionaltransport distance which exceeds 1,000m.

2. Point-to-multipoint transport can be realized.

3. Our particle conveying system adoptspiping fittings in diameters of 50-120mm, resulting in easy installation.

4. Low air consumption is ensured, and material and air ratio reaches 30-100.

5. Conveying speed is 6-12m/s. Pipeline is durable and materials are protectedfrom being damaged.

6. Reduced air discharge is responsible for easy cleaning and environmentprotection.

7. This powder conveying system comes withminimized mechanism devices, thus resulting in low maintenance load.

MainComponents

1.Silo Pump

This section comprises pressure vessel, feeding valve, discharge valve, airinlet valve, air outlet valve and fluidizing valve. The pressure vessel isdesigned to fit 8kg pressure. Materials are fed into the silo and transported bycompressed air.

2. Tuning Fork Level Switch

This device is used to test material level contained in silo. We offer allkinds of level indicators of various principles. Our dense phase pneumaticconveying system is fitted with tuning fork level switch which comprises

When power is on and material does not touch tuning fork, electronic circuitand piezoelectric resonator are generating vibration at certain frequency,leading to vibration of tuning fork. As a result, relay installed in our tuningfork level switch pulls in to send out non-contacting signal (not full).

When material contacts with fluid level sensor, vibration is stopped byresistance from material. Relay is released and contacting signal (full) issent out.

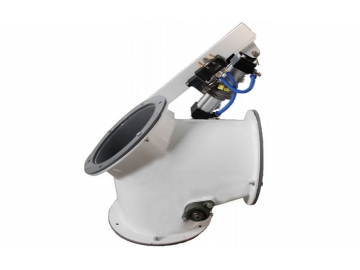

3. Pressure Switch

The pressure switch is used to detect the pressure of silo pump and controlsrelated valves.

4. Dust Filter

We introduce pulse jet fabricfilter to this dense phase pneumatic conveying system to achieve over 99% dustcollection and meet standards of environment protection. As for higherrequirements on environment, our pneumatic conveying system is compatible withmulti-level cleaning system, or the dust filter can be placed in outdoor.

Air supply device normally consists of air compressor, cleaning system and airtank. Screw type air compressor is generally employed for high efficiency. Thecleaning system meets demanding needs for clean air supply, and utilizes frozenmethod to remove water contained in compressed air. The air tank keeps pressureof compressed air for enhancing efficiency.

Title: Dense Phase Pneumatic Conveying System | CONLY

Keywords: Dense phase pneumatic conveying system, powder conveying system,particle conveying system, pneumatic conveying machine, pipe conveyingequipment

Description: CONLY dense phase pneumatic conveyingsystem utilizes compressed air to transport powder or particle materials insidepiping system. Point-to-multipoint transport can be realized.