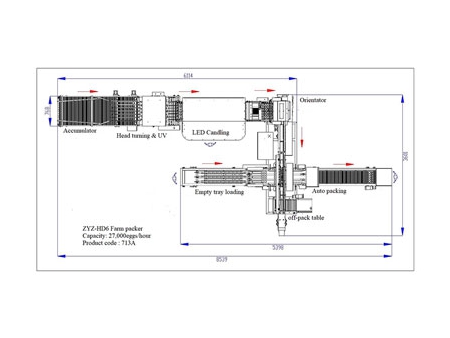

713A Egg Farm Packer (27,000 EGGS/HOUR)

ZENYER 713A egg farm packer with a capacity of 27,000 eggs/hour is designed to connect to a rod conveyor leading from the chicken shed for automatic loading purposes, as well as packing eggs into 5*6 egg trays automatically. It does NOT have a grading function.

The 713A farm packer includes accumulator, automatic head turning, auto packer (for 5*6 tray only), and optional UV sterilization and egg printer.

| Product name | Egg farm packer |

| Product code | 713A |

| Type | ZYZ-HD6 |

| Capacity | 27,000 eggs/hour |

| Main material | Stainless steel |

| Power* | 2.4KW |

| Voltage* | 380V, 50Hz, 3-phase |

| Dimension (L*W*H) | 8.3*3.6*1.5M |

| Net weight* | 950KG |

| Gross weight* | 1330KG |

| Function | Accumulator, automatic head turning, auto packer (for 5*6 tray only), and optional UV sterilization and egg printer |

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

- Accumulator

- Automatic head turning & UV sterilizing (optional)

- Auto packer (5*6 tray only)

- Off-pack table for test

- Egg printer (optional)

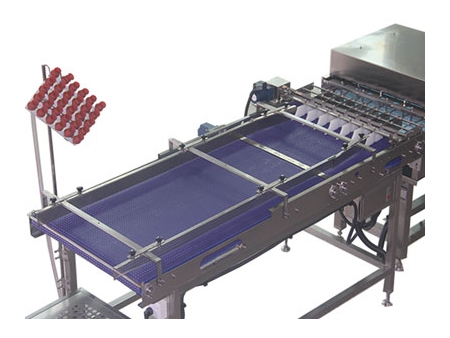

The accumulator connects with the rod conveyor leading from the chicken shed which delivers eggs directly from the chicken shed into the accumulator.

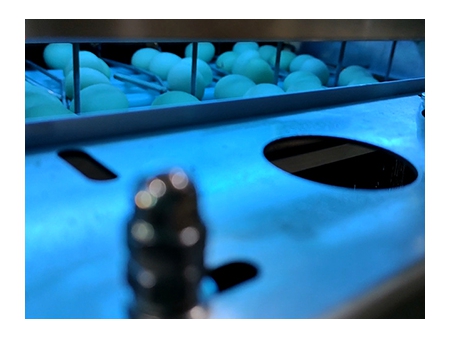

Then eggs go to the head turning and UV sterilizing section, the head turning makes sure the eggs are orientated with the bigger head (air chamber) on top for longer storage before getting packed.

It takes advantage of the UV disinfection system to sanitize egg shells for maximum food security.

The orientator will catch the 6 coming eggs from the accumulator, and send them to the next process.

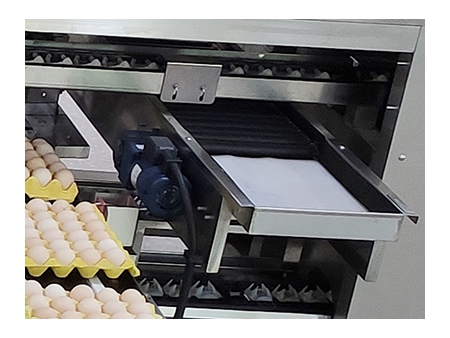

Empty trays need to be manually placed in the stocker, allowing the conveyor of the stocker to transport the empty trays to where the eggs will drop from.

The egg dropset auto packing system drops the eggs into 5*6 egg tray automatically.

There’s a control panel with a colour touch screen and physical buttons on the machine’s body, and also a physical button controller is equipped, which is on the side bar of the collection conveyor.

After automatic packing, the collection conveyor will transport the egg trays to the end of it. Workers collect the egg trays from there and pack them into the box.

The off-pack table at end of the machine is for egg dropping when testing the machine.

You can have a (6-print head) added on the collection conveyor if you want.