Batch Powder Coating Paint Booth

Request a Quote

Features

- COLO-S-2315 open-face powder coating booth suits for batch coating applications of small to medium work parts.

- Made of durable powder coated steel, the operating cost and maintenance are minimized.

- This operating size of spray booth is popular due to making efficient use of working space.

- Incorporates proven cartridge-filter technology, a clean working environment is ensured.

- High performance filter recovery system achieves efficient use of powder up to 98%.

- More precise parameters could be set via PLC controller conveniently.

| Model | COLO-S-2315 |

| Operating dimensions | 2300 width x 1500 depth x 1500 height mm |

| Overall dimensions | 2750 width x 2070 depth x 2180 height mm |

| Weight | 580 kg |

| Power supply | Electric |

| Nominal power | 4 kW |

| Voltage | 380V/220V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filter quantity | 4pcs (D325*H900 mm) |

| Hang type filter | Easy for change |

| Filter cleaning system | Pneumatic |

| Air consumption | 6600 m3/h |

Cartridge Filters

- Flexible color change is achieved by the quick-release type cartridge filters.

- Cartridge filter pleat design increases effective surface area and reduces powder waste significantly.

- Combines 4 pcs high precision cartridge filters, made of polyester with exact porosity allows for 100% separation of powders from airflow.

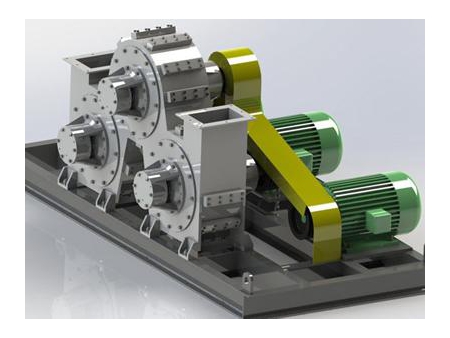

Fan

- The air in the workshop is drawn into the spray booth through exhaust fan, which drags the powder paint from the overspray towards filters for complete capture.

- Our aluminium fan is safe, durable and low noise with high suction performance.

Removable Powder Collector

- After filter cleaning, the discharged powders will be collected into a hopper beneath the unit, which can be taken away for fully emptying.

- The removable powder collector helps operators to recycle powder more conveniently.

- Such design increases powder utilization and provides cleaner powder recycling.

PLC Controller

- Full-function PLC controller offers more convenience to set or adjust parameters in a highly precise manner.

- Control panel includes power switch, fan start/stop switch, pulse cleaning timer, lighting switch and emergency stop button.

Filter Cleaning System

- Pulse-jetting filter cleaning controlled by solenoid valve prevents powder accumulation and extends filter life.

- The self-cleaning enables accumulated powders on the filter to be intermittently discharged into a recovery hopper beneath the filter stage.

Related Names

Powder Coating Room | Powder Coating Booth | Powder Coating Painting Booth | Powder Coating System | Powder Coating Workstation

Related Manufacturies

Leave Message

Similar Manufacturies and Parts

Manufacturer Advertising

More

Similar Manufacturies and Parts

Videos