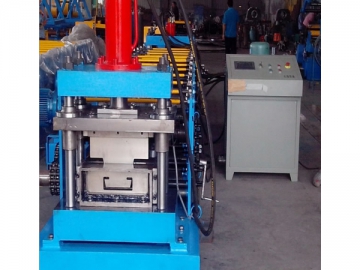

Z Channel Rolling Machine

The Z purlin made by our Z channel rolling machine features with excellent bending resistance, great toughness, and desirable straightness. The main spindle of the roll in this Z purlin machine is made of quality 40Cr material.

In practice, Z purlin, produced by our metal forming equipment has been used as the supporting structure of wall and roof, especially in plant, warehouse, garage, locomotive house, airplane shed, exhibition hall, cinema, stadium, market, greenhouse, and so on.

As a purlin roll forming machine, the Z channel rolling machine can be widely used in many industries like automobile, electrical project, building construction, and steel furniture.

Main technical parameter

1.Product size: 9500*1200mm

2.Production speed: 0-12m/min

3.Forming lanes: 14 groups

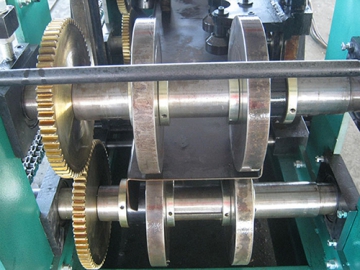

4.Target material: alloy steel GCR15 (bearing steel)

5.Frame materials: 300H steel (the side plate is assembled with 20mm steel which has been milled)

6.Quenching hardness of roll: HRC58-62

7.Roller quenching depth: 8mm

8.Roller quenching method: overall quenching in the salt bath furnace

9.Roller spindle: premium 40CR

10.Roll diameter: 80mm

11.Roll thermal treatment: thermal refining

12.Roller bearings: deep groove ball bearing 212

13.Rolling type: 140#-300# (thickness: 50-80mm)

14.Rolling thickness: thinner than 1.5-3mm

15.Configuration power: 22KW

16.Power of the converting motor: 2*1.5KW

17.Driving motor: M6-450 hydraulic motor

18.Fuel pump model: 40MCY14-1B plunger pump

19. PLC device manufacturer: Japan OMRON