UV Hybrid Printer (Roll to Roll and Flatbed)

Request a Quote

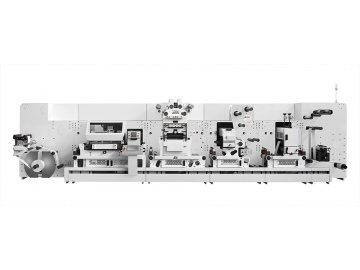

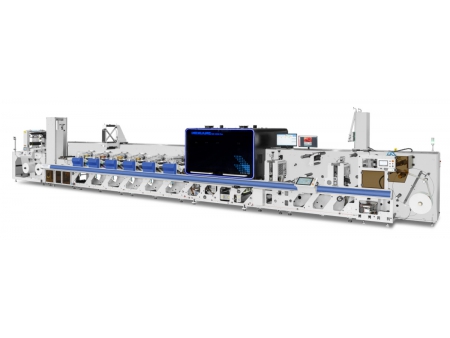

YD-H3200KJ

The YD-H3200KJ hybrid printer is equipped with 3-8 Kyocera industrial grayscale piezoelectric print heads. The number of the print heads can be adjusted according to your needs. The printing speed can reach up to 100㎡/h (4 pass), while the precision is 635*2400dpi. It can print rigid or flexible coils with width smaller than 3200. It is a high-speed coil printer especially designed for the advertising industry.

Application

Rigid materials: glass, acrylic, leather, wood board, metal sheet, PVC sheet, corrugated board, reflective film

Flexible materials: wallpaper, fabric, vehicle stickers and so on

Specifications

| Model | YD-H3200KJ | |

| Printing size | Width: 3200mm | |

| Model of print head | Kyocera grayscale piezoelectric print head | |

| Printing resolution | 635×2400dpi | |

| Number of printhead | 3-8 pcs (4-7 color options) | |

| Medium type | Rigid and flexible sheets | |

| Max. medium thickness | 50mm | |

| Input format | PDF, JPEG, TIFF, EPS, AI, etc. | |

| Printing speed | 4pass | 50㎡/h; double row 100㎡/h |

| 6pass | 35㎡/h; double row 70㎡/h | |

| 8pass | 29㎡/h; double row 58㎡/h | |

| Ink type | Environmentally friendly UV curable ink (VOC free) | |

| Ink color | Free combination of Lm, Lc, Y, M, C, K | |

| Special ink | UV white ink | |

| Power supply | 220V/AC (±10%) monophase, 50 / 60 Hz; 5 KW | |

| Printer dimension | 5800mm[length] × 1550mm[width] x 1500mm[height] | |

| Printer weight | 2050KG | |

| Operating environment | An independent clean workshop with low dust, little light and good ventilation. Ambient temperature: 18º ~ 30º (64º ~ 86º) Relative humidity: 30% ~ 70% (without condensation) Ventilation equipment: The overhead exhaust fan with the air displacement of 600 cfm is recommended. | |

Features

- It can print both coils and plates.

- For coil printing, the printer uses a constant tension control to ensure stable and reliable stepping.

- The printer uses a positioning device to ensure more precise printing of plates.

- The belt correction system makes the belt stay in the same position, realizing 24-hour continuous production.

- The optic grating sensor enables high-speed and high-precision printing.

- The constant pressure control technology effectively prevents the vibration of materials.

- Automatic material height measurement.

- Anti-collision system for print head trolley

- Two ink cartridges with double negative pressure system control separately white ink and color inks, ensuring a continuous ink supply during the printing.

- The printer is equipped with multiple emergency brake to ensure personal and equipment safety.

- The skip blank page function can automatically detect and discard blank pages.

- Two power-adjustable UV light tubes take turns according to the printing direction during the bidirectional printing, effectively reducing pass tracks.

- With a strong nozzle compensation function, the damaged nozzles can replaced by the normal nozzles to ensure that no blank or pass track will appear.

- Equipped with the intelligent RIP software, the printer can print the overlaped patterns, which greatly increases the output efficiency.

- The optional software template printing technology solves the problems of error in the splicing, so that the splicing error is less than 0.5mm.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos