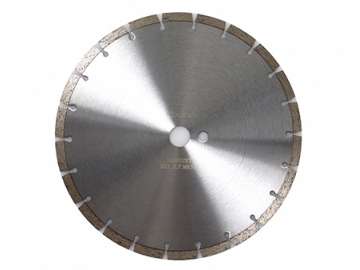

Wall Saw Blades

Valued Clients:

Please note, all product information has been updated, to view the latest information please click on the Navigation - Product. Thank you!

Brother Company offers a comprehensive range of wall saw blades which are made from the state of the art laser welding technology in the world. This ensures high welding precision and prevents teeth from being split off. In addition to that, the rugged cutting tools come with excellent sharpness and durability. They are designed with non-standard blade teeth that boast a height of16mm, with sharpness and service life 4 times increased than traditional12mmteeth, thus ensuring high efficiency.

1. Wall Saw Blade with Chromium Nitride Coating

With chromium nitride coating, this circular saw blade is more wear resistant in cutting stainless steel and alloy steel materials. Resistance in high speed rotating can also be reduced, thus extending blade lifespan and maintaining stability. In addition, cobalt is added to the blade to effectively improve blade stability, hardness, and wear resistance, and reduce friction coefficient.

Not only is this saw blade used for cutting wall, but it is also ideal for processing stainless steel pipes, bars and sections. It performs excellently in cutting common steel, aluminum alloy, plastic and wood.

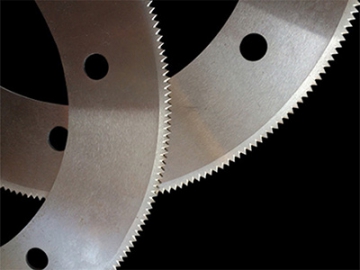

2. Wall Saw Blade with Oxidation CoatingThrough steam treatment, the sawing consumable comes with a layer of Fe3O4 on its surface. Due to that, the cutting blade has outstanding surface smoothness, cooling ability and less prone to getting stuck. Compared to the blades with other coatings, however, the saw blade comes with less cutting amount. It is the most frequently used saw blade.

Technical Parameters

Coating thickness: about 5-10μm

Surface hardness: about 900HV

Friction coefficient: 0.65

3. Wall Saw Blade with Titanium Coating

After the treatment of PVD coating, this sawblade enjoys a golden surface. The surface hardness is up to 2400HV that is approximately tripled over those in steam treatment. Friction coefficient is reduced to 0.55. It is used on semi-auto or fully auto metal circular saws for cutting seamless steel pipes, iron pipes and bars. The cutting speed is 2 times higher than that of steam treated blades, effectively reducing cost. In addition, it has outstanding effect in cutting stainless steel pipes.

Technical Parameters

Coating thickness: about 5μm

Surface hardness: about 2200-2400HV

Oxidizing temperature: 600℃

Friction coefficient: 0.55

4. Wall Saw Blade with Purple and Blue Coating

Via multi-layer of PVD coating treatment, the blade enjoys extremely low friction coefficient which makes it ideal for fine cutting works at high cutting speed and high amount of feed. It these works, it can obviously reduce scraps bonded on blade edge. This metal saw blade is perfect for cutting hard metals such as copper alloy and titanium alloy. Extremely high surface hardness enables it to cut high speed and large amount of feed extends its service life.

Technical Parameters

Coating thickness: about 5μm

Surface hardness: about 3000-3300HV

Oxidizing temperature:450℃

Friction coefficient: 0.25

| Specifications | Use | |

| 1. Laser welding for500mm-1200mmspecs. 2. Silver soldering, steel welding, high energy beam welding for1200mm-1800mmspecs. 3. Center hole diameter:60mm | 500mm×4.5mm×307×50mm | 1. Shearwall 2. Floor 3. Bridge 4. Tunnel 5. Building components |

| 600mm×4.5mm×367×50mm | ||

| 700mm×45mm×427×60mm | ||

| 800mm×48mm×467×60mm | ||

| 900mm×48mm×507×60mm | ||

| 1000mm×48mm×557×60mm | ||

| 1200mm ×48mm×657×60mm |