Blow Mold

We employ blow mold structural designers and manufacturers that have a minimum of 5 years' experience in the industry. They can carry out a complete analyses of the mold and product structure to solve potential problems that might occur in the molds or finished products by putting the molds through a series of in depth tests.

In addition to producing custom injection molds for plastic manufacturers in automobile, motorcycle, housewares, plastic pipe fitting, furniture and household appliance industries, we can also supply different blow molds for nearly any industry.

Product Range

We have produced blow molds for rocking horses, desks, chairs, plastic models, bottle parisons, plastic bottles, bus seats, sliding boards, automotive ducting, auto radiators, street lamp shades, stools, kid’s bikes, plastic cases, beach tables, and hollow chairs.

Blow Mold Maintenance

1. For blow molding that is transparent, the mold cavity should be highly polished periodically during container production. A polishing agent with a soft tissue paper can be used. Rub the cavity to allow a small amount of the polishing agent to be left on the surface, then wipe it with tissue paper until it appears to have a mirror-like appearance. Change the tissue paper regularly in order to avoid damaging the mold cavity.

2. If the blade of the parison clamping opening on the blow mold is becoming worn down, take it to a professional mold worker to be repaired.

3. It is important to keep the shearing block and shearing sleeve in good condition and replace them when necessary. If the shear block blades are worn unevenly, the finished blow molded container will leak at the neck.

4. If the cooling channel is clogged or corroded, clean it immediately.

5. The guide rod and the guide bushing of the blow mold need regular lubrication and must be replaced at least once a year to extend the service life of the blow mold.

6. When production is finished, and the blow mold will not be in use for a long period of time, clean the mold’s cooling channels by blowing compressed air into it and applying a protective agent onto the mold cavity to prevent corrosion.

-

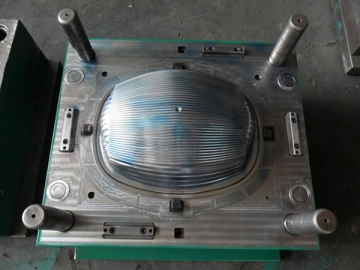

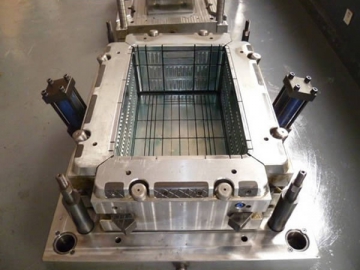

Blow mold for mineral water bottle -

Blow mold for feeding bottle -

Blow mold for bottle -

Blow mold for oil pot