Gear Inspection Machine

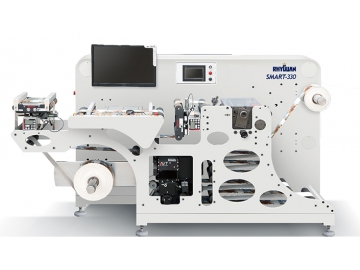

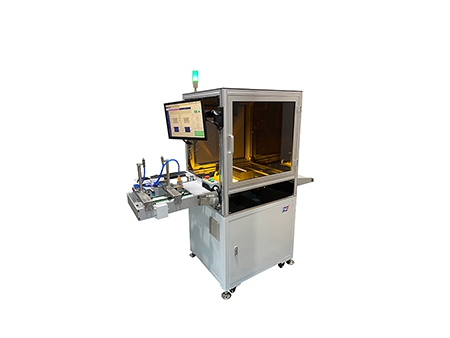

At NANO, as a prominent measurement solution provider, we offer customers a perfect solution for gear inspection. The HT series gear inspection machine is the solution that is a high-end, four-axis and full closed-loop CNC gear measuring center developed and manufactured by NANO by means of technological superiority in the industry.

The gear measuring machine employs generative measurement principle, and is composed of natural marble base, high precision rolling guideway, full closed-loop motion control system with high dynamic response, high precision micro-measuring sensor and high speed data collecting and processing system. Rational structure, extremely high rigidity, high measuring accuracy, stable indicating value and elegant appearance are what this series gear inspection machine provides for you.

The gear tester is used for measuring gears and gear products in all kinds of shapes such as straight and helical toothed cylindrical gears, hobs, slotting cutter, worm wheels, worms, straight and spiral bevel gears, etc.

Application Fields: The HT series gear inspection machines in multi models have served over 300 customers across the globe automobile, machine tool, electric motor, shipbuilding, metallurgy, mining, heavy duty machinery, industrial gears and other industries.

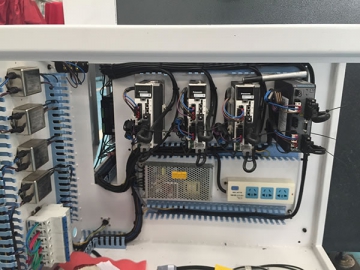

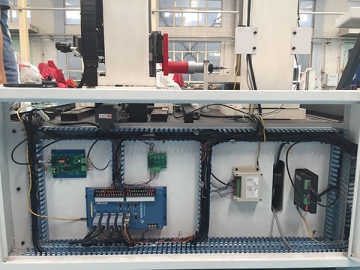

1. X-axis guideway is a high precision rolling guideway of THK brand. Aside from high precision, it ensures small compressive deformation, great dust proof performance, long service life, self-lubrication, etc.

2. The gear measuring machine employs a four-coordinate measuring system.

3. Measuring precision is dramatically improved by using imported direct drive motor, Japan made high performance AC servo motor, optical grating from Germany,RENISHAW linear grating from the UK, imported sensor and full closed-loop control system.

4. Machine base is made of natural marble which provides high hardness, excellent pressure resistance, less prone to deformation, great stability and small temperature difference.

5. X axis of the gear inspection machine employs a German made PC rolling guide screw that ensures not only high quality and high precision, but also high rolling stability.

6. Panasonic servo brake motor is used on the Z axis. It enables more reasonable structure, high motion stability, great indication repeatability, high indicating accuracy and low noise.

7. Dense ball bearings are used for rotation of Y axis.

8. Special auxiliary analysis software is used for reverse engineering of unknown gear parameters.

9. Assembly workers for this gear inspection machine are all from the branch factory of HMCT Group. They boast over 20 years assembly experience.

10. Measuring range is enlarged. For example, HT300 machine can be used to measure the gears with the maximum diameter of 350mm.

Technical Parameters| Model | ||||||

| Module | 0.5~6mm | 1~15mm | 1~20mm | 1~25mm | 1~ 25mm | 1~25mm |

| Max. outer diameter | 240mm | 350mm | 650mm | 800mm | 1000mm | 1200mm |

| Distance between centers | 10~400mm | 10~500mm | 10~850mm | 10~1000mm | 10~1000mm | 20~1200mm |

| Probe vertical measuring range | 260mm | 320mm | 360mm | 600mm | 600mm | 40~600 mm |

| Helix angle | 0~90° | 0~90° | 0~90° | 0~90° | 0~90° | 40~600 mm |

| Max. load capacity | 60kg | 150kg | 500kg | 800kg | 1000kg | 1200kgs |

| Resolution of inductive sensor | 0.0001 mm | 0.0001 mm | 0.0001 mm | 0.0001 mm | 0.0001 mm | 0.0001 mm |

| Scale resolution | Φ direction: 0.0002°; X, Z direction: 0.0001mm; Y direction: 0.0001mm | |||||

| Measuring gear accuracy | VDI/VDE 2612/2613-1 grade | |||||