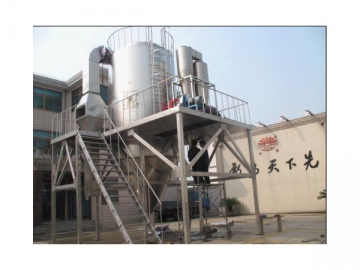

Centrifugal Atomizing Drying Equipment

Centrifugal Atomizing DryingEquipment

Descriptions

Spray drying is the widestused technology in the liquid shaping technology and in the drying industry. Centrifugal atomizing drying equipment is most suitable for producing powder,particles or solid block products from materials of solution, emulsion, soliquoid and pumpable pastestates. Therefore, spray drying is useful to create the desired particlesize, residual water contents, the stocking density, and the particle shapeneeded to meet precise standards.

Working Principle of the CentrifugalAtomizing Drying Equipment

After undergoing filtering and heating, air entersinto the air distributor at the top of the centrifugal atomizing dryingequipment. The hot air enters into the drying chamber in the spiral formuniformly. By passing through the high-speed centrifugal atomizer at the top ofthe tower, the material liquid will be rotated and sprayed into extremely finemist liquid beads. Through the very short time of contacting with hot air, thematerials can be dried into the finished products. The finished products willbe discharged continuously from the bottom of the drying tower and from thecyclone separator. The waste gas will be discharged by blower.

Features of theCentrifugal Atomizing Drying Equipment

1. The centrifugalatomizing drying equipment offers a fast drying speed. The material liquid issprayed in order to increase the surface area of the material, making it easierto dry. In the hot-air flow, 95%-98% of water can be evaporated veryquickly. The time to complete drying is only a fewseconds.

2. It is especially suitable for drying heat sensitive materials. The driedmaterials have excellent uniformity, mobility, and dissolving capacity, and thefinal products are high in purity and quality.

3. The production procedure is simple and the operational control is easy. Theliquid with a moisture content of 40-60% (for special materials, the moisturemay reach 90%) can be dried into powder or particle products quickly.After the drying, there is no need for smashing and sorting, so as to reducethe operation procedures in the production and enhance the product purity. Theproduct particle diameters, looseness and water contents can be adjustedthrough changing the operation conditions in a certain scope. The dryingequipment is very convenient to control.

Outlines

1. Atomization: the atomizing system must insure the fog drops aredistributed uniformly.

2. Contact of hot air flow and fog drops: It is vital that whenthe hot air enters the drying tower, the air flow is adequately heated.

3. The angle design of pipelines and cone: It is very important toselect the suitable angle. We can offer consultation and share the experiencewe’ve gained from producing thousands of pieces of this drying equipment.

Dried Samples

Our centrifugal atomizing dryingequipment can be used for drying a thousand types of materials. Details arelisted below.

Foodstuff : amino acid, vitamin, flavoring, protein, dried milk, pig bloodpowder, soy powder, coffee, tea powder, glucose, potassium sorbate,pectin, essence, vegetable juice, yeast, starch, etc.

Ceramics: alumina, zirconia, magnesium oxide, titanium oxide, magnesium titanate, pottery clay, china clay, all kinds of magneticporcelain and metal-oxides, etc.

Chemical Products: dispersed dyestuff, active dyestuff, organic catalyst,white carbon black, detergent powder, zinc sulfate, sodium metasilicat,potassium fluoride, calcium carbonate, tribasic potassium phosphate, inorganic catalyst, and all kinds of waste liquid.

Technical Parameters of theCentrifugal Atomizing Drying Equipment

| LPG Item | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||||||

| Inlet temperature( ℃ ) | 140-350 automatically controlled | ||||||||||||||||||

| Outlet temperature( ℃ ) | 80-90 | ||||||||||||||||||

| Method of Atomizing | High Speed Centrifugal Atomizer (mechanical drive or stepless frequency speed regulation is available) | ||||||||||||||||||

| Water evaporation capacity(kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||||||

| Revolution of atomizer(rpm) | 35000 | 20500 | 17600 | 15500 | 11570 | 10983 | |||||||||||||

| Diameter of Atomizing disc (mm) | 50 | 108 | 120 | 130 | 150 | 190 | 210 | 240 | |||||||||||

| Max Electric Heating Power(kw ) | 15 | 36 | 63 | 81 | 99 | Use other heat source | |||||||||||||

| Dried Powder Recovery Rate (%) | Around≥95 | ||||||||||||||||||

| Length of Covered Area(m) | 1.6 | 4 | 4.5 | 5.2 | 7 | 7.5 | 12.5 | 13.5 | 14.5 | Decided in accordance the flow chart, condition of field and requirement of customers | |||||||||

| Width of Covered Area(m) | 1.1 | 2.7 | 2.8 | 3.5 | 5.5 | 6 | 8 | 12 | 14 | ||||||||||

| Height of Tower Body(m) | 1.75 | 4.5 | 5.5 | 6.7 | 7.2 | 8 | 10 | 11 | 15 | ||||||||||

| Hoisting height of Nozzle(m) | -- | 2.5 | 2.5 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | ||||||||||

| Notes: The evaporated amount of moisture is contingent upon the characteristics of the raw material, solid content and temperature of hot air at inlet and outlet. Customers can choose the heating method according to the conditions of the local energy source. | |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We are a professional centrifugal atomizing drying equipmentmanufacturer in