Automotive Industry

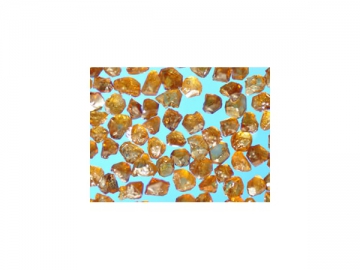

Super abrasives designed and manufactured by Funik are widely used in procession processing in the automotive industry. Every auto part requires stable and precision processing technology to meet the final requirement for reliability. Funik ultra-hard materials can adapt to even the most demanding milling, machining, grooving, grinding, turning and honing applications.

Our super abrasives can function throughout the entire automobile manufacturing process, and have a proven, outstanding performance in roughing and finishing of brake discs, brake drums, cylinders, and engine blocks. We work directly with our customers to develop tailored car processing tools and find solutions to meet their specific needs. Our partners have succeeded in implementing the solutions by using cubic boron nitride (CBN), polycrystalline cubic boron nitride (PCBN), and carbide.

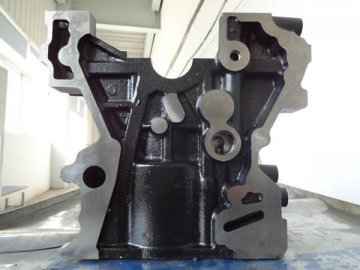

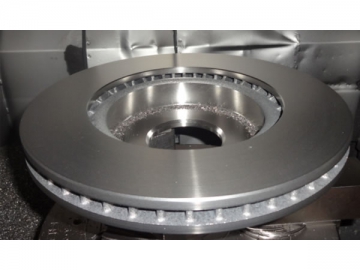

Brake Disc

Cutting tools for roughing: FBN7000 CNMN120716

Cutting tools for finishing: FBN7000 SCGN090412 S01015

Engine Cylinder

Coarse / semi-fine milling insert: FBN7025 SNGN0904ENS M08

For finishing the wiper blade: SNEX1204ZZ

Brake Drum

Cutting tools for roughing: FBN7000 CNMN120716

Cutting tools for finishing: FBN7000 WNMN080408

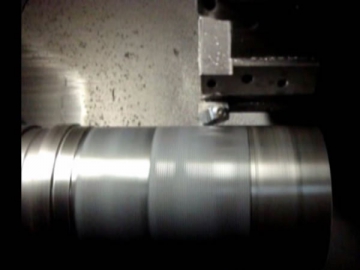

Cylinder Sleeve

Suitable cutting tool: FBN7500 SNGN120412 S02020

Compared to conventional tools and materials, our CBN products can achieve a more reliable cutting and grinding process for engine and power plants around the world. The come with higher cutting and grinding speeds, a longer tool life, lower operational costs and a higher efficiency.

Work piece: engine block end surfaces

Material: HT250

Processing method: dry cutting, finishing

Original cutting tool: coated carbide cutting insert

Current cutting tool: Funik's FBN7025 SNEN090412

Efficiency comparison: 01:03

Life comparison: 01:02

About the Customer

The customer company came to us and had been using the coated carbide cutting insert of a well-known brand from abroad, and they tried several new coated carbide cutting inserts and PCBN inserts to improve production efficiency, but those tools failed to meet the task requirements. Finally, they used Funik cutting inserts, and effectively gained the cost effectiveness they were looking for by having 8 knife tips.

Customer Feedback

In 2012, we tried several cutting tools from large manufacturers to process the end surfaces of engine blocks. With speeds only around 2,000 rpm, they did not meet our expectations. Funik's CBN cutting tools surprised us with a speed of 2,550 rpm and a feed rate up to 3,670mm/minute. The efficiency was more than doubled, and the top life was extended by nearly 50%. What's more, Funik's cutting insert has 8 tips, which is 8 times more than common inserts found on international markets. This greatly reduced our costs.

Work piece: brake disc

Material: HT200

Hardness: HB170-210

Processing method: Roughing

Original cutting tool: Japanese coated carbide cutting tool

Current cutting tool: Funik's FBN7100 CNMN1207

Efficiency comparison: from 50 seconds/piece to 20 seconds/piece, the processing time is shortened by 30 seconds

Life comparison: from 45 pieces/edge to the 120 pieces/edge, life expectancy is 2.7 times longer

About the Customer

A huge market potential has spawned a large number of brake disc enterprises in China to develop, and the competition among small and medium enterprises is fierce. Cost control is a key factor in winning this battle. This particular case is about an auto part manufacturer in Yantai, China. The customer had been using a Japanese coated carbide cutting tool to make brake discs. The efficiency is low, and the life is short, while the cost is high. The company's development was seriously restricted by these negative features.

Expert Review

Our CBN ultra-hard cutting tools are starting to be used more and more within the auto parts industry. For different work pieces, we continue to develop new products to solve various processing problems. After learning, in detail, the processing problems the customer was having, we studied and propsosed a series of solutions, which have brought a number of encouraging results. With a high cost-effectiveness, the PCBN cutting inserts continue to be used by large foreign and domestic companies.