Mines

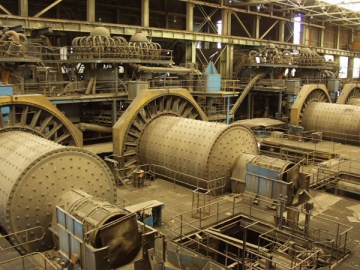

Grinding Balls and Cylpebs Applications in Mines

During the ore grinding work of grinding balls or cylpebs in mines, their grinding quality and fineness to ores have the direct bearing on the purity and quality of finished minerals. In the course of minerals processing and beneficiation, grinding is one of the most frequently used processes. Except the minority of people who use autogenous mills and pebble mills, the majority (over 98%) select grinding balls or cylpebs as mineral grinding media.

In China, the consumption of steel balls used for grinding minerals in only metal mines is up to 500,000 tons every year. Choosing premium steel balls as grinding media in mines can not only reduce steel consumption, thus bringing great economic and social benefits, but also be of great importance in improving ore grinding capacity, increasing beneficiation handling capacity and reducing unit energy consumption.

HUAZHENG can provide specialized wear resistant grinding balls for all kinds of mining enterprises. Our steel grinding balls are available in 14 kinds of specifications. Their diameters range from Ф20mm to Ф125mm. Since the minerals come with various properties and huge difference in grindability, the ball mills adopted by different mining enterprises have different performances.

In addition, although under the condition of same grinding fineness, the single separation degree of useful minerals and gangue minerals is varied. On the grading and quantity of steel grading media balls, HUAZHENG can offer you the optimal solution, reducing your cost and risk in mining works.