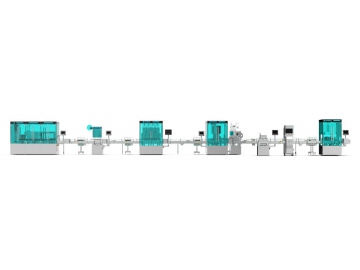

Capsule Slip Ring Production Line

Injection Molding

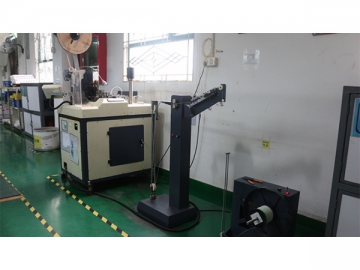

Injection Molding Automatic wire cutting, stripping and tinning line

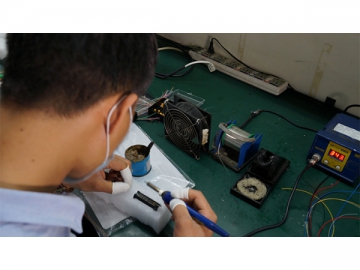

Automatic wire cutting, stripping and tinning line Brush welding

Brush welding Steel ring welding

Steel ring weldingPictured on this page is a dust-free workshop, which is focused on the production of one of our chief products: the capsule slip ring. As early as in 2013, we improved the wire cutting, stripping and tinning process that traditionally required 3 workers to complete. The improved process now needs only one man to take care of, which saves labor all the while improving production speed.

A full view of dust-free workshop

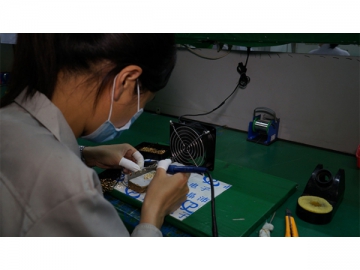

A full view of dust-free workshop Capsule slip ring assembly

Capsule slip ring assemblyThe workshop was built in 2012, which is a class 100,000 clean room. This dust-free facility is the first of its kind in Chinese slip ring industry, which ensures the cleanliness of the resultant product and minimizes the contact resistance fluctuation.

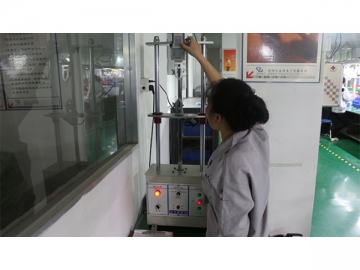

Tensile Test

Tensile Test Static, dynamic resistance fluctuation test 1

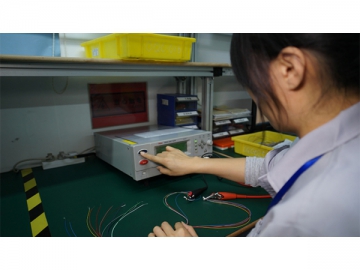

Static, dynamic resistance fluctuation test 1 Finished capsule slip ring conductivity test

Finished capsule slip ring conductivity test Insulation resistance tests

Insulation resistance testsIn-house Tests

1. Each and every of finished capsule slip rings needs to go through a conductivity test. Disqualified product will be weeded out for rework.

2. Inspectors randomly check the tensile strength of the capsule slip ring. (The product is pulled until it snaps.)

Finished Product Tests

1. An improved test method is used to check static and dynamic resistance fluctuation. A maximum of 24 circuits can be tested in one operation.

2. Conductivity test (All products need to be tested.)

3. Insulation resistance

4. Mechanical property

5. Appearance check