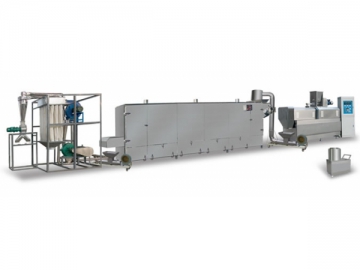

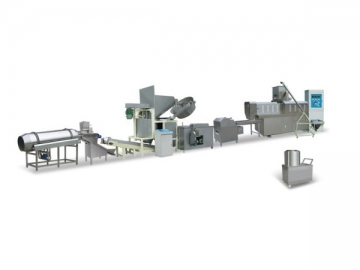

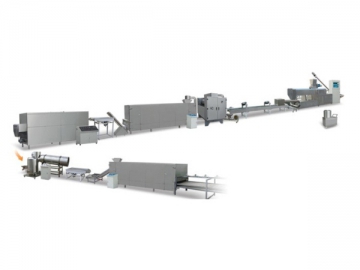

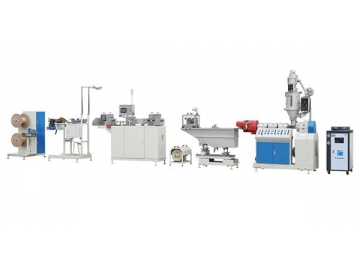

Co-extrusion System / Line

Nothing beats snacks with center fillings. In the twin-screw extruder, both the extrudate and filling are combined into concentric streams at the die before they are shaped into pillows, tubes or bars. Fillings can be of virtually any flavor. Creams, chocolates, and peanut butter are typical. Co-extruded snacks have a richer flavor than ordinary ones. Their cuts can be curved or straight, open or sealed.

Qidong's range of co-extruded snacks processing lines provides a wide choice of outputs from 100kg/h to 600kg/h, and a great amount of automation that allows feeding, extrusion, filling, shape formation, drying, and coating to be done automatically. Key parts including the co-extrusion die can be changed over quickly to a different snack shape. Better still, this co-extruded snack production line can be retrofitted to produce fried snacks.

Co-extrusion Process Flow

1. Mixing

The choice of mixer should be based on the yield of the co-extrusion Line. We offer three mixer types for option.

2. Feeding

Uses an auger conveyor for transfer of raw materials, which is powered by an electric motor.

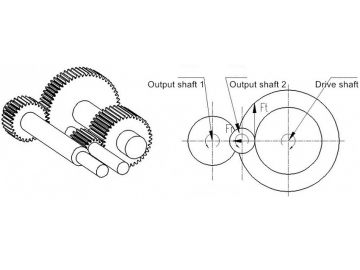

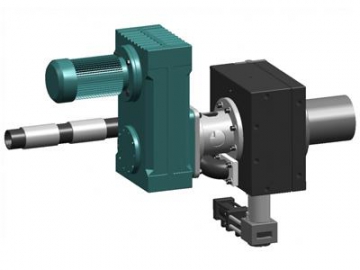

3. Co-extrusion

This co-extrusion process can take cornmeal or rice as raw material and put them into cereal snacks.

4. Cream Feeding

The cream feeder shoots cream into the extruder.

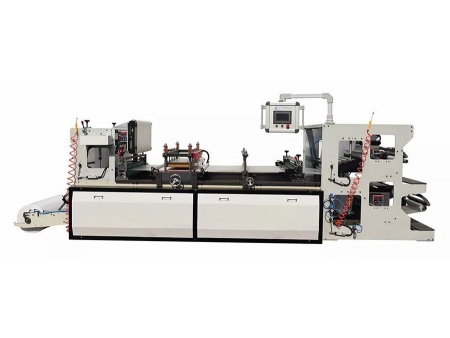

5. Cut-off

A specialized cutter cuts the continuous strand emerging from the holes of the extrusion die to length. This step is necessary, as the cut snacks are easier to bake and pack. Cut length and speed are adjustable.

6. Lifting

Co-extruded snacks are transported to a higher position where they are baked in an oven. A pneumatic conveying blower is available for option.

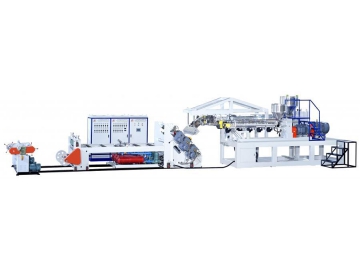

7. Multi-Tier Conveyor Oven

Temperature inside the multi-tier conveyor oven (mostly electrically powered) is adjustable up to 200°C from the control cabinet. Double-layer wire mesh bags are made of stainless steel. Drying time is easily controlled by speed adjustment. Both the fifth and seventh tiers (or decks) are of stainless steel construction.

8. Vibratory Screening

Removes scraps, crumbs, and crusts.

9. Flavoring

Various drum configurations are available.

| Model | Installed Power | Power Consumption | Motor Power | Output Capacity | Installed Dimensions |

| 35KW | 22-30KW | 22KW | 100-200KG | 15×2.5×4M | |

| 45KW | 30-35KW | 30KW | 150-300KG | 16×2.5×4M | |

| 55KW | 35-40KW | 37KW | 300-500KG | 27×2.5×4.5M |

Service Package

1. Co-extrusion snack recipes

2. Snack shapes

3. Free-of-charge installation and commissioning

4. Operator training

5. One-year quality guarantee

6. Choices of system length from 16m to 27m. We can arrange the co-extrusion Line straight or curved.

7. Engineers offer to design and configure the co-extruded snack system free of charge, based on customer-provided factory specifications.