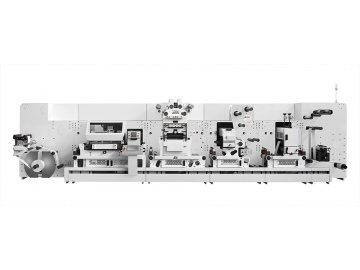

Digital UV Flatbed Printing Machine

YD-F2513R5-40

YD-F2513R5-40 digital UV flatbed printing machine introduces Ricon print head, a universal accepted one, which supports a simultaneous printing for different pictures and the printing for certain area of single picture. Thus, mass printing for small pictures and sampling printing for big picture could be easily achieved.

The UV flatbed printing machine allows six color printing with a high resolution of 600*2400dpi and a high speed of 36m2/h (4 Pass), thus the mass printing requirement could be perfectly met. If you are looking for a UV printing machine for the printing of high-end material, YD-F2513R5-40 digital UV flatbed printing machine will be your ideal choice.

YD-F2513R5-40 Digital UV flatbed printing machine is applicable to print varied materials, including glass, acrylic, wood sheet, ceramic tile, metal sheet, PVC board, corrugated board, corrugated box, wine case, plastic materials and etc.

| Model | YD-F2513R5-40 | |

| Printing size | 2500×1300mm | |

| Print head model | Ricoh grayscale piezoelectric print head | |

| Printing resolution | 600*2400dpi | |

| Printing speed | 4 Pass | 36㎡/h |

| 6 Pass | 27㎡/h | |

| 8 Pass | 20㎡/h | |

| Printing mode | Unidirectional & bidirectional | |

| Ink color | Lm, Lc, C, M, Y, K for option | |

| Print head | 2~8 (4~8 colors for option) | |

| Ink | Eco-friendly UV curing ink (with zero VOC –volatile organic compound) | |

| Special ink | UV white ink or transparent vanish | |

| Printing material thickness | Max. 400mm | |

| Printing materials | Both rigid and flexible materials | |

| Applicable printing materials | Glass, acrylic, wood sheet, ceramic tile, metal sheet, PVC board, corrugated board, plastic materials and etc. | |

| PIP | PhotoPrint,Onyx | |

| Input software | Adobe Postscript Level 3, PDF, JPEG, TIFF, EPS, AI | |

| Power supply | 220V/AC(±10%)single phase,50/60HZ;6KW | |

| Weight | 1350KG | |

| Dimension | 4510mm×2500mm×1400mm(L×W×H) | |

| Operation environment | A separate cleanroom with low level of environmental pollutants such as dust, small illumination, and good ventilation; Ambient temperature: 18º ~ 30º (64º ~ 86º) Relative humidity: 30% ~ 70% (zero condensation) Ventilation equipment: Overhead exhaust fan with a displacement capacity of 600cfm is advisable. | |

- The ink cartridge is designed into a drawer, a brand new design, which offers much convenience for ink changing and the maintenance for ink supplying system.

- Handle is installed close to operation table, so the format size of vacuumizing zone could be easily controlled.

- Printing worktable is divided into four equal units, so the control unit's size could be chosen freely in accordance to actual printing format.

- A computer is introduced to control printing machine's operation, leading to an easier operation and an increased operation space.

- A control panel is outfitted in the front part of our YD-F2513R5-40 digital UV flatbed printing machine, which allows a user-defined printing.

High quality components

- Three to eight Ricoh grayscale Micro piezo TFP print heads, featuring internal heating and optional for 4~7 colors (six color or 6 color plus two white ones) are introduced for our YD-F2513R5-40 Digital UV flatbed printing machine. Its ink droplet size is adjustable from 7pl to 35pl, so an intense droplet, multi-color printing, picture resembling printing accuracy, even 2pt knockout space, could be realized. Not only high printing accuracy, an efficient printing with a high resolution of 600*2400 dpi, a durable and stable Ricoh print head are also available for our printer. So it is quite suitable for long-period operation. With proper maintenance, when our printer works in 24 per day, a 5-year service life could be achieved.

- Tempered double guide track, made of steel frame, is introduced to our digital UV flatbed printing machine, so it enjoys a stable, smooth and efficient working.

- Drag chain introduced from IGUS, a German company, timing belt introduced from Megadyne, an Italian company, are all outfitted in Yotta's YD-F2513R5-40 digital UV flatbed printing machine, so it could work stably and reliably in a long period of time.

- Many emergency stop brakes are installed in our printer, so both the operator and the equipment's security could be ensured.

- Yotto's digital UV flatbed printing machine is also outfitted with a backup power supply, so when there is a power off, negative pressure system could still work as usual. In this way, the printing machine could be activated in a quite short period of time when there is a power on.

Humanized designs

- Instead of manual measurement, automatic height meter is installed in our printer for the measurement of print head height and printing material amount. Thus, both an improved printing efficient and printing accuracy are achieved.

- Professional charging and discharging devices are outfitted, so finished printing materials with a wide format and heavy weight, could be taken out easily and conveniently.

- The working mode of vacuum table could be altered when there is a shift between air blowing and air absorption. When air absorption is adopted, a reversing for airflow will be required for precise printing on flexible materials.

- The UV printing machine is designed with an anti-collision system which enables an automatic stop of print head trolley when there is an attach between printing material and the trolley. This design effectively protects the trolley and printhead from damage.