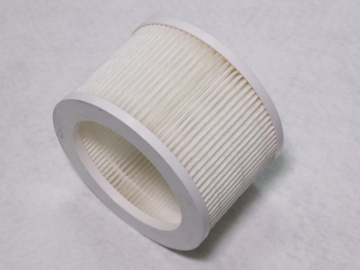

Filter Materials

Request a Quote

The raw materials used in the production of air filters are extremely important as they directly impact filtering effectiveness and efficiency. Regarding floating particles or gaseous contaminant filtering, we would select the type of material based on the following information.

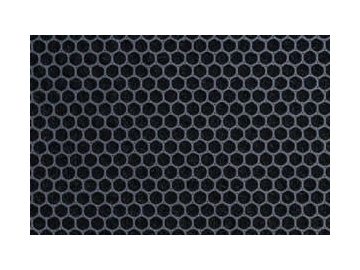

Main material for filtering solid particle- Plastic mesh, polyester fiber mesh, metallic mesh, etc.: these materials provide low resistance, high air permeability, and are suitable for coarse air filtration, intercepting hair, dust, and large contaminants. These filters have a long shelf life, are useable after washed, environmentally friendly and economical.

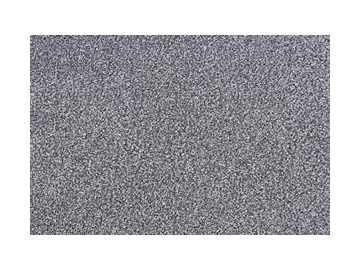

- PP melt blown fiber, these materials are woven tightly and have low resistivity and high filtration efficiency. They are suitable for medium high efficiency air filtering.

- Glass fiber: suitable for any environment, high stability, filtration is possible thanks to its unique physical structure. Suitable for high requirement environments such and pharmaceutical production, operating ward, high precision cleanrooms, etc. Areas where a filtering precision of H13 and above is required normally use glass fiber filtering mesh.

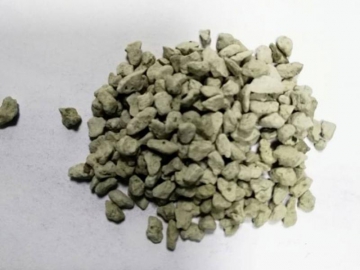

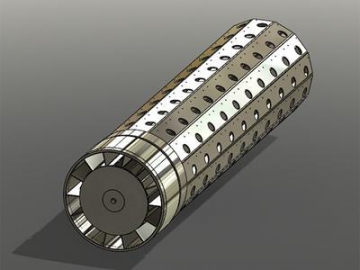

- Activated carbon, molecular sieve, activated alumina, zeolite, diatom, carbon fiber, etc.: These materials all have a robust microporous structure, large surface area, and are able to adsorb gaseous contaminants. We can choose different types of material according to the particle size of the contaminant. These are mainly for physical filtration.

- Chemical filtration: Select carbon, particle filters, activated alumina as carriers impregnated in chemical products or precious metals to eliminate harmful gases. For instances, after the impregnating process, the filtering material can remove formaldehyde, ammonia, H2S, etc.

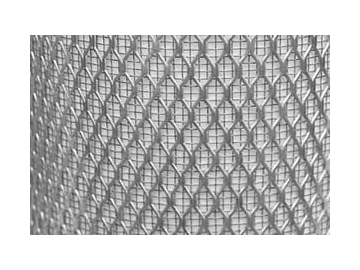

- Composite filter paper: these materials undergo special treatment using HEPA filtering mesh and activated carbon, namely activated carbon cloth. These materials are suitable for household filters, vehicle air conditioning and factory ventilation systems.

- Anti-bacterial/virus filter paper: these materials undergo copper ionization, resulting in long lasting anti-bacterial/viral capabilities. They can trap and eliminate staphylococcus aureus, E. coli, H1N1, etc. Suitable for all kinds of filters.

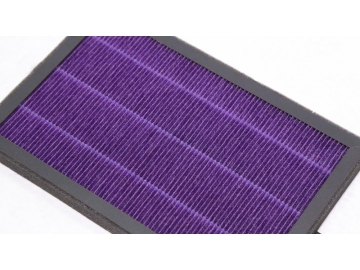

- Metal oxide photocatalyst: Metal oxide photocatalyst is a kind of semi conductive material coated on the substrate. It can undergo violent catalytic degradation when exposed to UV light. Effectively degrades harmful gases, eliminating bacteria, neutralizing toxic gas released by bacteria or fungi, while removing formaldehyde, odors, contaminants, and purifying air. Suitable for all kinds of air filters and odor removal systems.

- Acid, alkaline neutralization: Impregnated carbon material in acidic or alkalic chemicals. Usually used for neutralizing industrial acidic or alkalic corrosive gases.

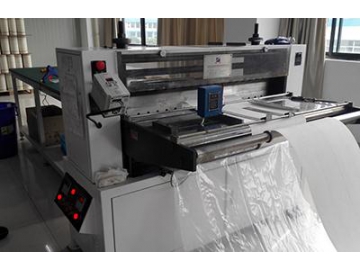

- Passing material inspection stages, ensuring its performance according to different classifications, adhering to EN779:2012 standards. The inspection result of our inspection station is identical to the result of the US TSI8130 automation inspection device.

- Passing the 1 cubic testing chamber, analysis the odor removal capability, such as CH3O, NH3, O₃, H₂S, Toluene, Xylene, etc.

- Passing the iodine level and CTC adsorption level test for activated carbon.

Let us introduce several types of material

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos