Improving Cold Storage Warehouse Working Efficiency

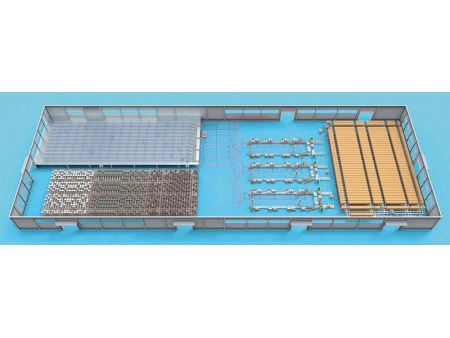

The use of cold storage has covered in all aspects of food transportation, storage and distribution. However, because cold storage rooms have an extremely large power consumption, there are a number of things a customer can take into consideration when designing a cold storage room in order to increase the energy efficiency ratio as much as possible, and thus, lower operating costs.

1. Selection of refrigerating unit

Different refrigerating units have different energy consumption rates. Choosing a highly energy efficient refrigeration will reduce the power consumption of the cold storage room.

2. Cold Storage Lighting System

With a goal of saving energy, the energy consumption of the lighting system should be reduced as much as possible while also taking into consideration science, safety and rationality. Therefore, choose a system that reduces the power consumption in the lamps, while also reduces the lamp heat radiation levels.

3. Thermal insulation of cold storage

Thermal insulation in a cold storage room will directly influence the start-up frequency of the cold storage unit. Frequent startups increase power consumption and reduce the service life of the refrigeration units.

Most often Howcool uses 200mm boards for the construction of a freezing cold storage room, and a 100-150mm board for other cold storage rooms.

4. Timely defrosting for air cooler

The frost thickness on the air cooler will directly affect the fan's cooling efficiency. Defrosting on a regular basis will reduce power consumption.

5. Releasing oil, descaling and outgassing regularly

Data shows that when the oil film thickness reaches 0.1mm, the evaporating temperature is reduced by 2.5°C in order to maintain the set temperature. This in turn increases the power consumption by more than 10%. When the scale thickness on the water wall in the condenser reaches 1.5mm, condensing temperature will rise 2.8 ℃ when compared to the original temperature, which increases the power consumption by 9.7%. If there is non-condensable gas and its partial pressure reaches 0.196MPa, power consumption will be increased by almost 18%.

By releasing oil, descaling and outgassing on a regular basis, users can ensure an excellent heat transfer effect and a better energy saving performance.

6. Reasonable temperature usage difference between day and night

In a marine environment, temperature differences between night and day ranges between 6-10℃, however, in a continental climate area, that difference increases 10-15℃.

If night time ambient temperatures are low, the startup period at night can be adjusted based on the product storage needs. The condensing temperature is relatively low, which is great for saving energy in cold storage.