Air Compressor for Laser Cutting

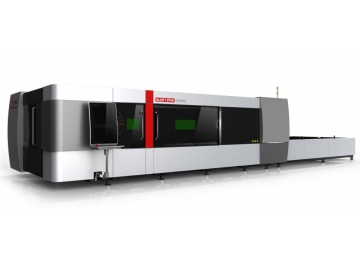

Laser cutting machines are a staple in metal fabrication. Yet, their efficiency and output quality often hinge on auxiliary systems like post-treatment air compressors. Many businesses underestimate this, risking both product quality and equipment health. HAREYES post-treatment air compressors are designed to mitigate these risks, offering a comprehensive solution for your laser cutting needs.

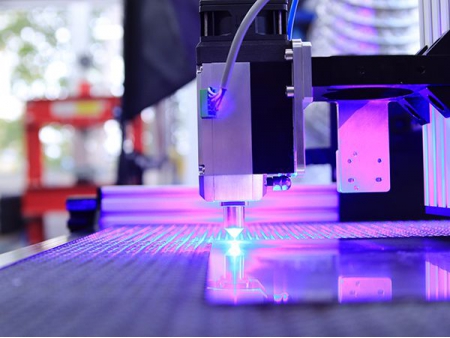

Compressed air serves a triad of functions in laser cutting processes: it acts as a protective gas supply, a power source, and a dust-removal agent. When a laser cutting machine is in operation, the use of protective gases is imperative. Air compressors compress a mixture of air, high-purity oxygen, and nitrogen, supplying this cutting gas to the cutting head. Concurrently, another portion of compressed air fuels the pneumatic cylinders of the clamping worktable. A third stream of compressed air is directed to clean the optical path system.

The air, once expelled from the air compressor, undergoes filtration and drying through an air storage tank, precision air filters, and modular desiccant dryers. Then it is divided into three separate streams to serve the three above-mentioned purposes. In summary, air compressor is not just an add-on for laser cutting operations; it's a necessity for the smooth functioning of any laser cutting equipment.

Our experts are happy to answer all your questions and concerns as well as sales and after-sales service.