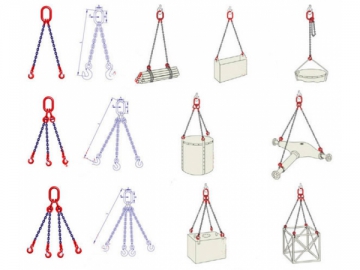

Steel Lifting Chain Maintenance

1. Please do not distort the steel lifting chain.

2. Please immediately solve the problem of scratch, stop or abnormal wear if appeared.

3. If there will be chemical substance or severe corrosive condition in the steel lifting chains’ work environment, please contact us and request an order of special steel chain.

4. Please regularly check the steel lifting chain’s length and wear condition to look out the deformation and surface damage. The chain should be cleaned before being checked. Please avoid the cleaning method that may cause hydrogen embrittlement or overheating or may cover up the cracks and surface defects. Technicians should have complete inspection on every hoist chain. The requirements are as follows:

(1) The hoister’s double stranded long chains must be used in pairs. If the scratch, stop and partial overload make the chains’ length longer than the tolerance, the lifting chains must be timely repaired or replaced in pairs.

(2) The hoist chain’s permissible wear value should not exceed 10% of the chain’s diameter. If exceeded, the steel chain must be scrapped.

(3) Please regularly check the steel chain’s elongation. If the elongation is 5% longer than the standard length, the chain must be scrapped.

(4) Please do not use the steel chain products that have cracks, bend, twist, surface damage or unsolvable problems of stiffness, stagnation or resistance between the rings.

(5) If the steel lifting chain has some individual rings being 4%-6% longer elongation or individual parts obviously worn, the chain should be timely repaired or replaced.

5. Please remember the following points:

(1) The industrial chains should not be repaired by customers themselves. If the hoist chain needs repair, please send the chains to us. Alternatively, we can send our professional technicians to guide the repair.

(2) The lifting chains should not have reprocessing treatment, such as welding, heating, heat treatment, chemical treatment on surface, etc.

6. The chains’ link and toggle clip must have tight coupling with the hopper. All the threaded connections must be checked once a month and timely fastened if loose.

7. Appropriate safety couplings or safety pins should be configured to prevent the damage caused by overloading.

8. It is strictly prohibited to soak the lifting chains in water or corrosive solution; or pile the chains in wet or open environment for long time.