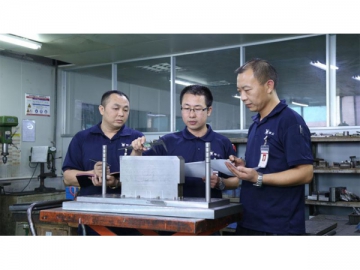

Equipment Manufacture

Most equipment manufacturers can benefit from the use of rust prevention products, since they provide cleaning, protection and even lubrication for critical metal parts that are prone to rust or easy to attract dirt or moisture. CVCI is a professional VCI packaging material producer. We at CVCI understand that each machinery maker may have his or her own requirements for rust prevention products. Just as importantly, there are wide-ranging needs across the equipment manufacturing industry. Providing the right rust protection product for each and every customer typically requires great expertise. That is why at CVCI, we design each corrosion management solution according to the material, process and storage applications. Whether it is a small motor or a complete set of construction equipment that you want to pack, our company is sure to deliver the right corrosion preventative packaging for you.

I. Metalwork

1. Metal Tools

Typical Application: Saw blades

Construction: Tool steel

Rust Prevention Requirements: A dry, less-than-10µm thick film provides rust protection that lasts for at least 1 year. The oil film should be uniformly distributed on the saw blade surface and look transparent.

Solution: Apply rust preventative oil onto the saw blade by dip and dry it out with hot air to for a hard film on the blade surface.

2. Metal Wire Rope

Typical Application: Steel cord

Construction: High quality carbon steel coated with copper

Technical Requirements: An Oil-free system provides rust protection that lasts one year.

Solution: Use VCI paper as interleaving between coils of steel wire. Wrap the entire coils with high-strength laminated film packaging.

3. Metallic Cookware

Typical Application: Electric rice cooker

Construction: Rust-prone parts are mainly the heating plate which is made of aluminum-iron alloy.

Technical Requirements: Safe, eco-friendly, with rust protection that lasts 1 year

Solution: Apply specialized VCI paper and seal the heating plate with polyethylene bags.

II. General Purpose Equipment

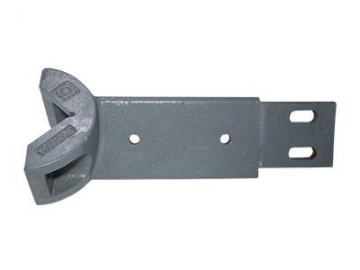

1. Boiler and Associated PartsTypical Application: Blower parts

Construction: Cast iron base and multiple metal parts

Technical Requirements: Blower parts need to be transported outdoors without outer cover. Rust prevention measures should make sure the whole package is waterproof, tightly sealed, and provides rust protection for at least 6 months.

Solution: Wrap fast around internal surfaces of the blower, add VCI powders and desiccants inside it, and use VCI shrink wraps to pack from outside.

Typical Application: Turbine rotor

Construction: High-strength steel

Technical Requirements: Turbine rotor needs to be preserved in dry air. High-barrier material is needed, coupled with desiccants. 1-year rust protection is required.

Solution: Reinforced VCI aluminum-poly film is used with desiccants. Vacuum out the enclosed packaging space before sealing.

Typical Application: NC lathe

Construction: Multiple metals

Technical Requirements: The NC lathe needs to be packed in a wooden crate. Rust prevention measure is needed, which should maintain its effectiveness for at least 1 year.

Solution: Pack the internal surface of NC lathe with VCI film. Add VCI powders to critical parts that prone to rust. Exposed metal parts need to be oiled with VCI liquids.

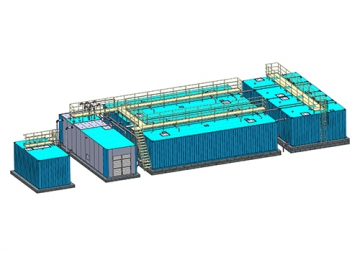

Typical Application: Paper and board machine

Construction: Multiple metals

Technical Requirements: Export shipments that need to be packed in wooden crates and protected against corrosion for 1 year.

Solution: Pack the inside with VCI film and paper. Exposed metal parts should be protected with water-displacing rust preventative oil.