Laser Processing Machine for Pipes

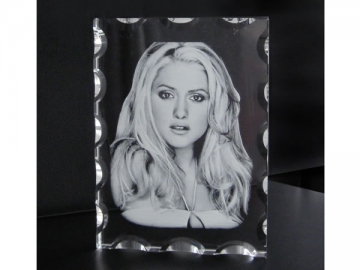

1. Marking applications: marking logo, letter, serial number, barcode, and 2D matrix on pipes

Recommended model(s): Fiber Laser Marking Machine, Diode Side-Pump Laser Marking Machine

Advantages: Compared with traditional process, laser marking is more efficient, environmental-friendly, and cost-saving.

2. Welding applications: welding stainless steel pipe with customer's tooling

Recommended model(s): Fiber-Coupled Laser Welding Machine, YAG Laser Welding Machine

Advantages: Traditional argon arc welding (TIG welding) needs secondary polishing and other processing. It results in wide welding seam, which will rust after some time. In comparison, laser welding has narrower welding seam and higher precision. It does not require secondary processing, and the welding part will not rust.

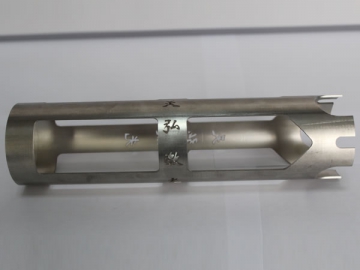

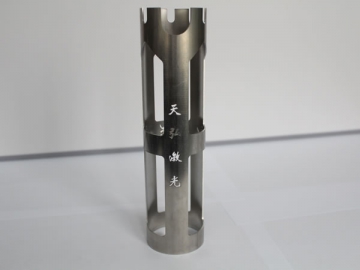

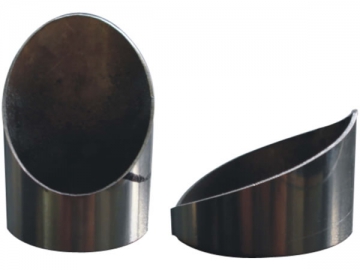

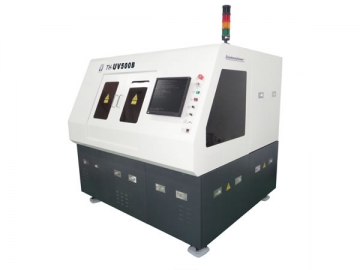

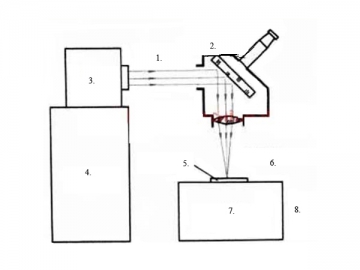

3. Cutting applications: stainless steel pipe cutting, carbon steel pipe cutting

Recommended model(s): Fiber Laser Cutting Machine, 3D Fiber Laser Cutting Machine

Advantages: Compared with traditional process, laser cutting has higher speed and precision. Batch processing can be achieved with it, which improves working efficiency and saves costs.