Laser Welding Machine

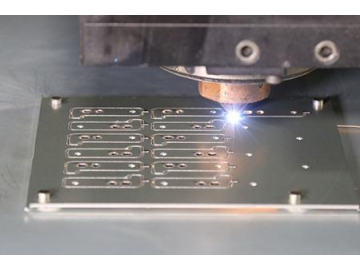

Compared with traditional argon arc welding machine, the laser welding machine is more economical, more convenient, and has better welding results. Laser welding has narrower welding seam and higher precision. It is more durable and more efficient with no need for secondary processing. It is also free from the rusting problem of argon arc welding on stainless steel material. One can do stitch welding, butt welding, and welding between different materials with the laser welding machine.

When welding, the laser welder emits laser beam with high power density (108-1012 W/cm2), and then the beam is focused to bombard the target surface, generating heat and melting the workpiece.

The laser beam is a coherent light beam having single frequency, and the transmission does not produce divergence. Polycondensation of the lens can focus it into a certain size (diameter of 0.076 to 0.8 mm). Small focus can be used for welding, cutting and perforating, and big focus can be used for heat treatment of the surface. The laser beam can be guided to any direction by the mirror, so the laser welding machine can weld parts of the workpieces that are inaccessible for ordinary welding. Optical fiber guidance will further the flexibility of laser welding.

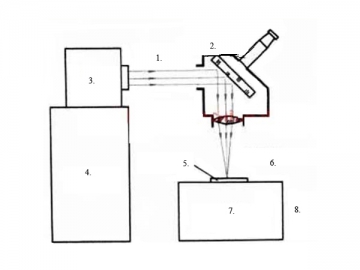

1. Laser beam

2. Focusing system

3. Laser generator

4. Power supply

5. Workpiece

6. Focusing

7. Work table

8. Laser welding machine drawing

Related Names

Laser Welder | Laser Welding System