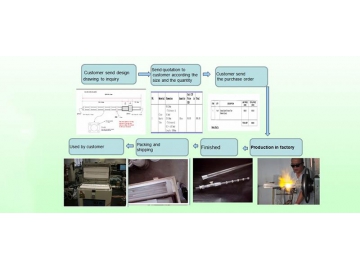

Business Workflow

| Technical Communication | Mould Design | Customer Confirmation | Purchase | Machining |

| Order | ||||

| Customer | ||||

| Mould Delivery | Mould Inspection | Sample Confirmation | Sample Delivery | Assembly & Mould Trial |

Kelon is amazingly characterized by DFM, Design For Manufacturability. We believe optimal design results in unsurpassed stability in finished moulds and cost effective production process. Therefore, our efforts have firmly been emphasized on feasible design and making our plastic injection moulds and stamping dies as fabulous blend of technology concept and economic efficiency.

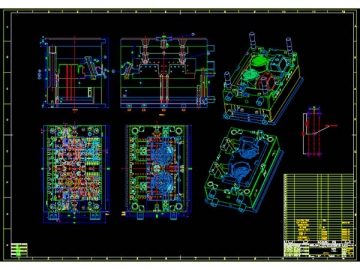

1. Mould design

Normally, the design takes 7 to 10 days. What we need from customers is comprehensive information including 3D picture, 2D picture and DFM data. The DFM data comprises product information, mould information, sprue layout, parting surface analysis, water line layout, structure details and modification advice, etc.

In design period, if problems occur, such as complexity, hard processing or infeasibility, we will do our best to give suggestions to work things out.

2. Customer confirmation

After receiving confirmation on design from customer, we will immediately implement material purchase and processing technique programming. We will utilize advanced IM3, the exclusive management system for mould manufacturer, to take over order handling, control on mould processing plan and workshop, as well as management on quality and inventory.

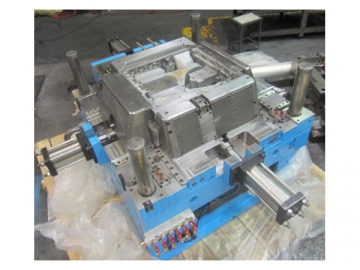

3. Mould processing and assembly

We take advantage of Plan Control and Workshop Control modules for mould processing control in a holistic approach. Progress chart is regularly sent to customer for reference on processing plans and real-time progress.

The Plan Control module shows each abstract procedure into intuitive time point. The intricate mould processing can be managed in a holistic approach via the control on each time point.

The Workshop Control module consists of Production Management and Workshop Operation. Every detail of each procedure is presented in this module and we set the working schedule in accordance with standard labor time to restrain worker operation, thus promoting efficiency and quality.

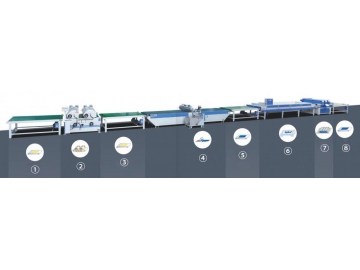

4. Sample delivery

We will finish mould processing and sample testing within T1 (First testing) time scheduled in contract. The sample will be sent to customer via DHL for assembly or other testing.

5. Testing and modification

We will use CMM or digital caliper for inspection and measurement of moulds. Data obtained will be sent to customers for reference. Based on customer feedback on T1 sample testing, necessary modification will be made to ensure that mould meets customer’s expectation.

An inspection visit to our plant is possible. We will make arrangement for the coming customers to make them feel at home.

6. Delivery

After obtaining final confirmation from customer on product and mould, delivery time will be settled down. We will perform mould cleaning, painting and packaging, as well as delivery.