SMT Red Glue

SMT red glue is a kind of polyene organic compound. Compared to solder paste, the red glue will cure after it is heated. Its curing point is 150℃, after this, it immediately changes from paste to solid. Its outstanding curing speed, high heat-resistivity, and excellent electric properties make this a vital component in soldering. It is ideal for processing SMT series during wave soldering processes.

Specifications before curing| Item | Testing condition | Properties |

| Composition | - | Epoxy resin |

| Appearance | Visual inspection | Red color gel |

| Homogeneity | 25℃, fineness meter | < 100μm |

| Gravity | 25℃ | 1.25 g/cm³ |

| Viscosity | 25℃, 5rpm | 450,000cps |

| Trixtropy Index | 1rpm/10rpm | 6.7 |

| Yield Value | 25℃, Haak RV1 Cone plate rheometer, PK100,PK1/1o | 300~650Pa |

| CASSON Viscosity | Same as above | 0.15~1.8PaS |

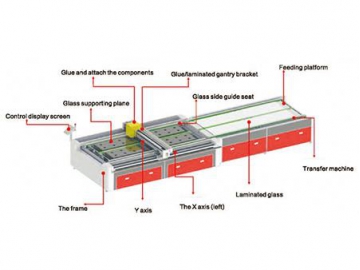

| Application process | - | Screen printing, dispensing machine |

Recommended curing condition

The recommended curing condition is 90~120 sec after surface temperature has reached 150℃, or 160~180 sec after surface temperature has reached 120℃. The highest curing temperature should not exceed 200 ℃. The ideal curing condition depends on the curing furnace. With a higher curing temperature and longer curing time, the stronger the adhesive strength. The typical curing curve of red glue is as follows:

| Item | Testing condition | Properties | ||

| Adhesive property | Lap shear strength | 25℃,steel - steel | >15MPa Mpa | |

| Thrust | 25℃, C1206-FR4 copper plate | >40 N | ||

| Tg | TMA | 80℃ | ||

| Adhesive spot diameter growth in curing | SJ/T 11187-1998 | < 10% | ||

| thermal expansion coefficient | α1 | TMA | 60×10 -6 K -1 | |

| α2 | 120×10 -6 K -1 | |||

| Volume resistance | 25℃ | 2.2×1015 Ω·cm | ||

| Surface resistance | 25℃ | 2.2×1015 Ω | ||

| Dielectric strength | 25℃ | 25 KV/mm | ||

| Dielectric constant | 25℃, 1MHz | 3.2 | ||

| Dielectric loss angle tangent | 25℃, 1MHz | < 0.02 | ||

Curing conditions

Absent the presence of special instructions, the curing condition will be 150 ℃ for 30 min. The actual adhesive strength of red glue largely depends on the type of component, shape of the glue point, and the curing degree of the glue.

- With the one-off syringe packing type, it can be used on normal dot dispensers.

- The red glue should be preserved in a refrigerator maintain quality. Before processing, it should be taken out from the refrigerator and placed down vertically for de-freezing in room temperature (ideal temperature for 20~25℃) about 2~4 hours until it reaching the room temperature. Hot water, oven, hot plate, heat gun and other heat sources should not be used to speed up de-freezing. This step is extremely important for obtaining optimal dot dispensing performance.

- There might be a few interspaces between the needle and its protective cover, which is a normal phenomenon during production. Before use, take the protective cover down and squeeze out a small amount of glue manually to empty the air in the front end.

- To avoid cross contamination of glues, the dot dispenser must be cleaned before equipping it with a syringe.

- The amount of dot dispensing depends on pressure, time, needle diameter and glue temperature. The above parameters should be gradually optimized according to the actual situation.

- Before curing, it can be cleaned by isopropyl alcohol solvent, acetone solvent, butanone solvent and esters solvent. After curing, it can be cleaned only by heating and mechanical removal.

Related Names

Solder Removal Products | Circuit Soldering Accessories | PCB Soldering Wick