Turntable Shot Blast Machine

Request a Quote

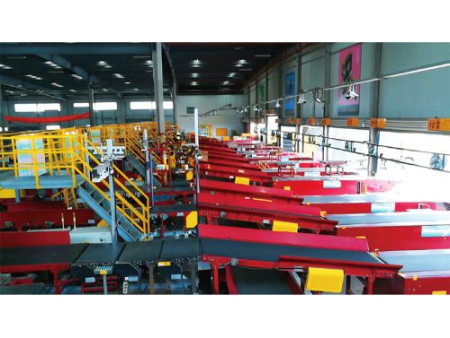

This turntable shot blast machine is used for cleaning and strengthening the surface of both structural steel and castings. It is more suitable for removing rust and scale from the surface of steel billets of high thickness. Our product is widely applied in such industries as casting, forging, machinery, iron and steel, among others.

- Structure

This product is a turntable shot blast machine with simple and compact structure. It is mainly composed of the chamber, turntable, auger conveyor, separator, elevator, impeller head, dust removal system, and other parts. At the top of the chamber, there are two fast-rotating impeller heads. The impeller head allows the abrasive shot material to be rapidly propelled, and then hit the workpiece rotating on the turntable. When rotating out of the chamber, the workpiece has been obviously cleaned, and simultaneously it is replaced by the new workpiece. - Working Principle

Inside the turntable shot blast machine, the rotating turntable will force the abrasive shot material to rotate. With the help of the auger conveyor, the sand mixture will be sent to the lower part of the elevator. Then, it will be lifted by the elevator to the separator. The separated shot material will be stored in the hopper of the separator. It will continue working for the impeller head, after passing through the pipe and the baffle plate. - Transmission Mechanism

The speed reducer of our turntable shot blast machine will put the friction wheel in motion. Through a clutch system, the turntable will be forced to stably rotate. After the workpiece rotates out of the chamber, the transmission system can be used for directly turning and regulating the workpiece being not cleaned. Also, it can pull the clutch handle to separate the friction wheel from the turntable, in accordance with different types of cleaned workpieces as well as the difficulty of loading, unloading and turning work. In other words, the turntable will stop rotating. It will begin to rotate again, after the workpiece has been adjusted and the position of handle has been changed.

Technical Parameters of Q35 Series

| Model | Q3512 | Q3525 |

| Sized of Cleaned Workpiece (mm) | 600×250×250 | 1000×500×250 |

| Max. Weight of Workpiece (kg) | 400 | 100 |

| Blasting Capacity (kg/min) | 200 | 2×250 |

| Lifting Capacity of Elevator (t/h) | 15 | 30 |

| Separation Capacity of Separator (t/h) | 350 | 150 |

| Ventilation Volume (3/h ) | 2400 | 6200 |

| Power (except for dust removal) (kW) | 17.3 | 35.2 |

| External Dimension (mm) | 1500×3450×3760 | 2200×3500×4300 |

Technical Parameters of Q36 Series

| Model | Q365c | Q3610 | Q3620 |

| Size of Cleaned Workpiece (mm) | 2500×1300 | 2500×1500×280 | 4000×3000×700 |

| Max. Weight of Workpiece (kg) | 500 | 1000 | 2000 |

| Blasting Capacity (kg/min) | 2×250 | 4×250 | 4×250 |

| Lifting Capacity of Elevator (t/h) | 40 | 60 | 75 |

| Separation Capacity of Separator (t/h) | 40 | 60 | 75 |

| Ventilation Volume (m3/h ) | 13200 | 24000 | 21000 |

| Power (except for dust removal) (kW) | 39.2 | 188.45 | 185.25 |

| External Dimension (mm) | 9000×4200×9290 | 14900×500×1700 | 16900×6540×10020 |

Technical Parameters of Q76 Series

| Model | Q765c | Q7610 | Q7620 | Q7630 |

| Size of Cleaned Workpiece (mm) | 2000×1000 | 2500×1500×280 | 4000×3000×700 | 4000×2000 |

| Max. Weight of Workpiece (kg) | 5000 | 10000 | 20000 | 30000 |

| Blasting Capacity (kg/min) | 2×250 | 3×250 | 4×250 | 4×250 |

| Lifting Capacity of Elevator (t/h) | 30 | 45 | 60 | 60 |

| Separation Capacity of Separator (t/h) | 30 | 45 | 60 | 60 |

| Ventilation Volume (3/h ) | 11000 | 15000 | 21500 | 21500 |

| Power (except for dust removal) (kW) | 35.8 | 188.45 | 183.35 | 83.2 |

| External Dimension (mm) | 9000×5200×9290 | 14900×5200×6100 | 16900×6540×10028 | 9151×7680×10874 |

Related Names

Steel Shot Blasting Machinery | Sand Blasting Equipment | Metal Surface Preparation Equipment

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos