Bottled Water Production Line

At Dahong, we not only provide stand alone blow molding machines and bottle fillers, but we also pride ourselves on the complete bottled water production line we've made for customers around the globe.

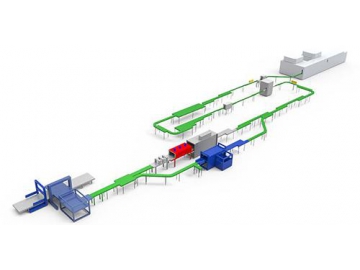

Our complete bottled water production system is made up of many heavy duty components, including the blow molding machine, belt conveyor, bottle filling machine, bottling labeling machine, shrink wrapping machine, barcode label applicator and bundle stacker.

We provide solutions not just standard products. If you are in the market for bottled water production line, Dahong can help.

Bottled Water Production Process

PET Flakes---The raw material of choice for producing bottle preforms (also called blanks, baby soda bottles or giant test tubes)

Injection Molding --- PET flakes are melted and extruded into tube-like bottle preforms at high temperature and pressure.

Blow Molding --- Heating the bottle preform softens it. Pressurized air inflates the tube to the shape of finished bottles.

Conveying --- Blow molded bottles are moved onto the inline conveying system, typically a pneumatic conveyor

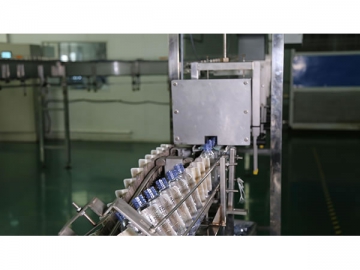

All-in-one Washing, Filling and Sealing System---Uses clean water to wash the inside bottle, fills it with water and caps it off.

Inkjet Printing --- Prints dates of manufacture on the bottle's exterior. Bottle Labeling --- Applies labels to the bottle.

Shrink Wrapping - A specified number of bottles are shrink wrapped as a bundle to facilitate transportation.

Film Wrapping ---Boxes of bottle bundles are put on one pallet and wrap them with plastic films to facilitate storage.

Warehousing--- Puts finished products on in the warehouse and ready to be launched onto the market.