Rust Removal

The removal of rust, scale, oxides or other contamination is required before coating, plating, anodizing or other secondary finishing. Rust removal can not only improve the appearance of your workpiece but also the performance. Several common ways to remove the rust: manual removal, chemical removal, flame descaling and mechanical rust removal.

Manual rust removal is the most primitive method with high labor intensity, low efficiency, unstable finishing quality, which usually exists rust residual after processing. It can't apply to mass finishing and can only be used by the hand workshops.

Chemical rust removal features high efficiency and low cost. But chemical media could bring dissolution and huge damage to the workpiece. Furthermore, residuary acid on the surface can cause secondary rust.

The principle of flame descaling is that, the metal surface and the oxides possess different coefficients of thermal expansion and the oxides rust will peel off earlier after heating. But this method can result in workpiece distortion and incomplete finishing performance.

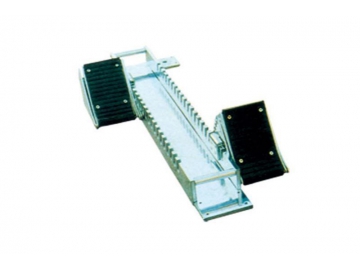

Mechanical rust removal features high efficiency and excellent descaling performance and various abrasives can handle the corresponding various workpieces.

With experience of over decade years in mechanical rust removal equipment manufacturing, we are very clear what techniques an excellent rust removal machine requires. We stick strictly to the normative production procedures to finish the workpieces, which has received many praises from our customers. If you have any need for rust removal equipment, please feel free to contact us.